What is a Safety Valve? - Full Guide

Introduction: The Unsung Guardian of Industrial Safety

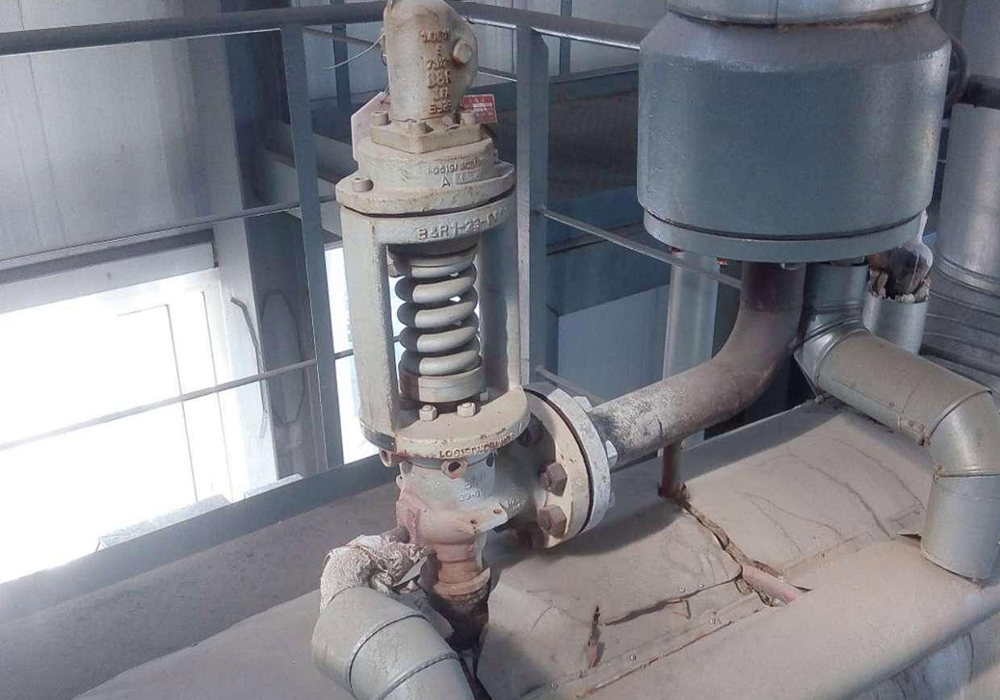

In complex pressurized systems, few components are as critical—or as overlooked—as the safety valve. At first glance, it looks like just a small metal piece—nothing special, honestly, about the size of your fist. But it does an important job: it stops too much pressure that can cause accidents, explosions, damage, or hurt people.

This guide will show you what safety valves are, how they work, where to use them, and why choosing the right one matters. Whether you’re an engineer making sure things meet safety rules or someone buying parts you can trust, this guide is for you.

1. What is a Safety Valve? — The Technical Definition

A safety valve is a device that opens by itself when the pressure gets too high, letting some pressure out to keep things safe. It protects vessels, pipelines, boilers, and pressurized equipment from potential rupture or failure caused by excess pressure.

Key Characteristics:

• Automatic: Opens without external control.

• Pressure-sensitive: Activated by internal pressure buildup.

• Resetting: It closes again once the pressure goes back to normal.

• Fail-safe: Designed to function even in emergency conditions.

Laws require industries like power plants, chemicals, oil and gas, food, ships, heating, and medicine to use safety valves.

2. A Brief History: From Steam Engines to Modern Industry

The concept of pressure relief dates back to the early 18th century during the rise of steam power. James Watt’s steam engines were some of the first to use basic safety valves. These valves helped stop boiler explosions caused by too much steam or human error.

As industrial applications evolved, so did safety valve technology. Today’s safety valves must follow strict international rules like ASME, EN ISO 4126, and API 526/527. These rules help make sure the valves work well, even in dangerous situations.

3. How Does a Safety Valve Work? – The Physics Behind It

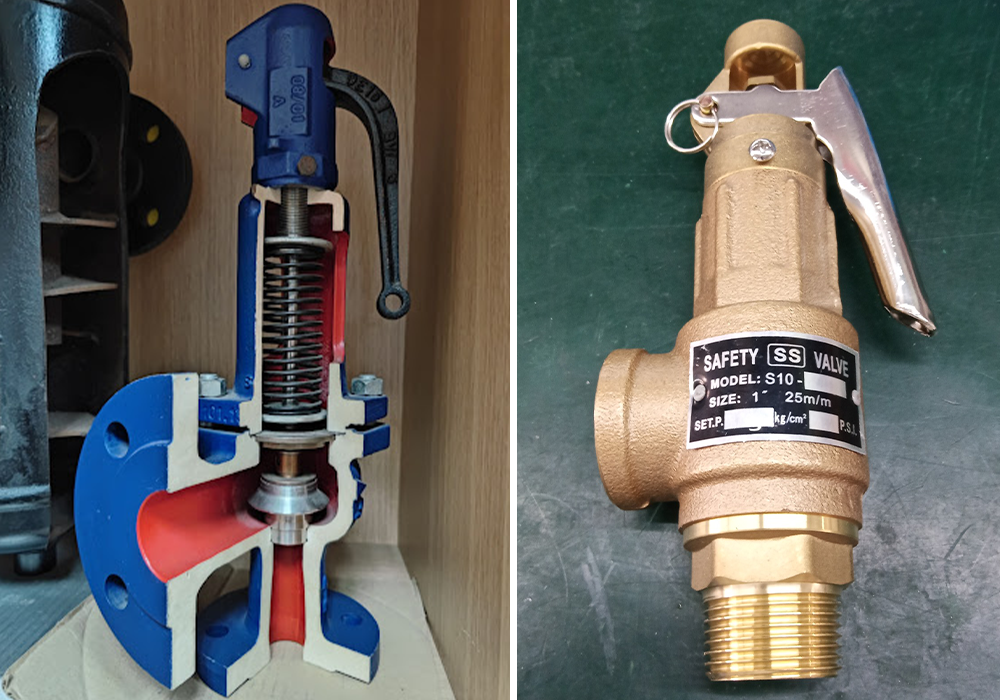

The operation of a safety valve is based on mechanical equilibrium. Here’s how a typical spring-loaded safety valve works:

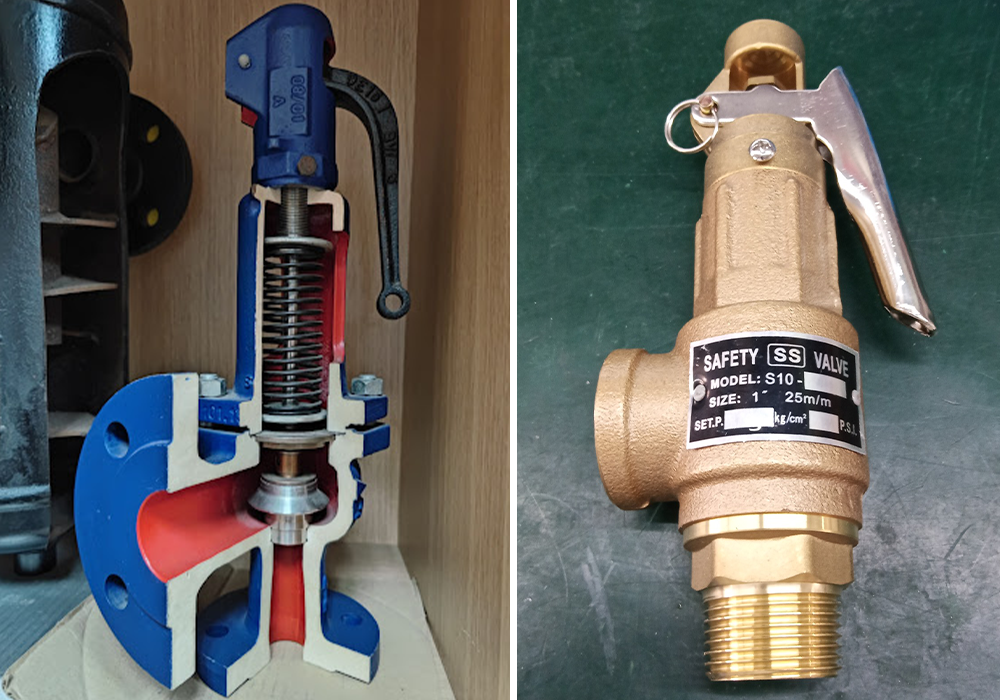

3.1 Normal Operation:

• The valve disc is pressed against the seat by a calibrated spring.

• The force from the spring is greater than the system pressure.

• No flow occurs; the system operates safely.

3.2 Overpressure Occurs:

• System pressure exceeds the setpoint.

• The upward force on the disc surpasses the spring force.

• The valve “pops” open, rapidly releasing excess fluid or gas.

3.3 Pressure Relief:

• The escaping fluid reduces system pressure.

• Some designs allow for “blowdown,” keeping the valve open for a short while to ensure full pressure relief.

3.4 Reseating:

• Once pressure falls below a safe threshold (reseating pressure), the spring pushes the disc back into place.

• The valve closes, and normal operation resumes.

4. Main Types of Safety Valves

Safety valves are not one-size-fits-all. Engineers choose each type of safety valve based on the application, environment, and type of pressure involved.

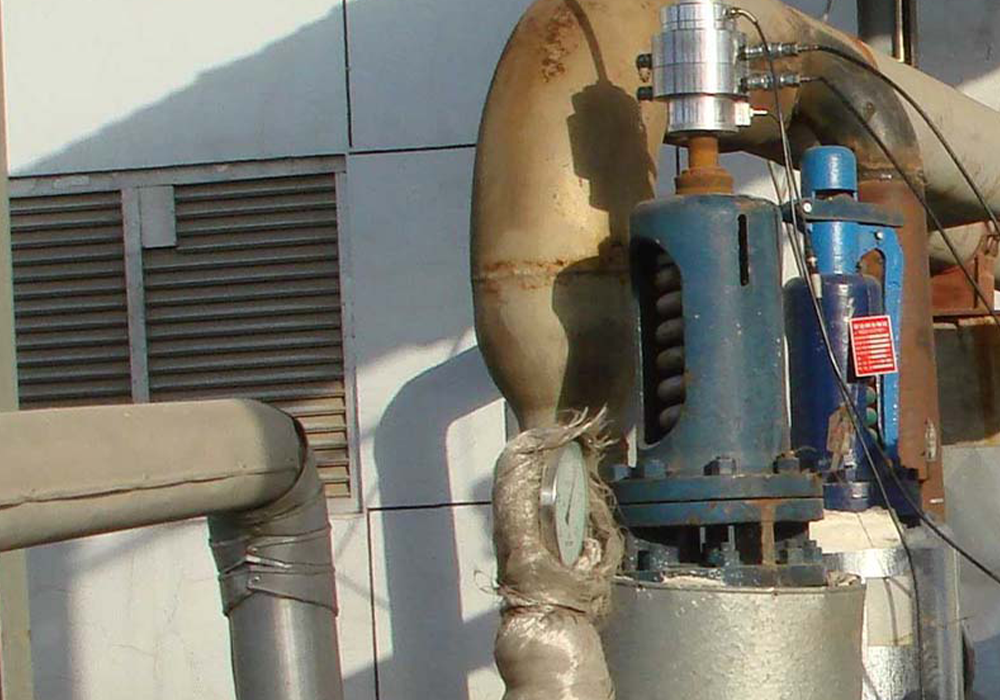

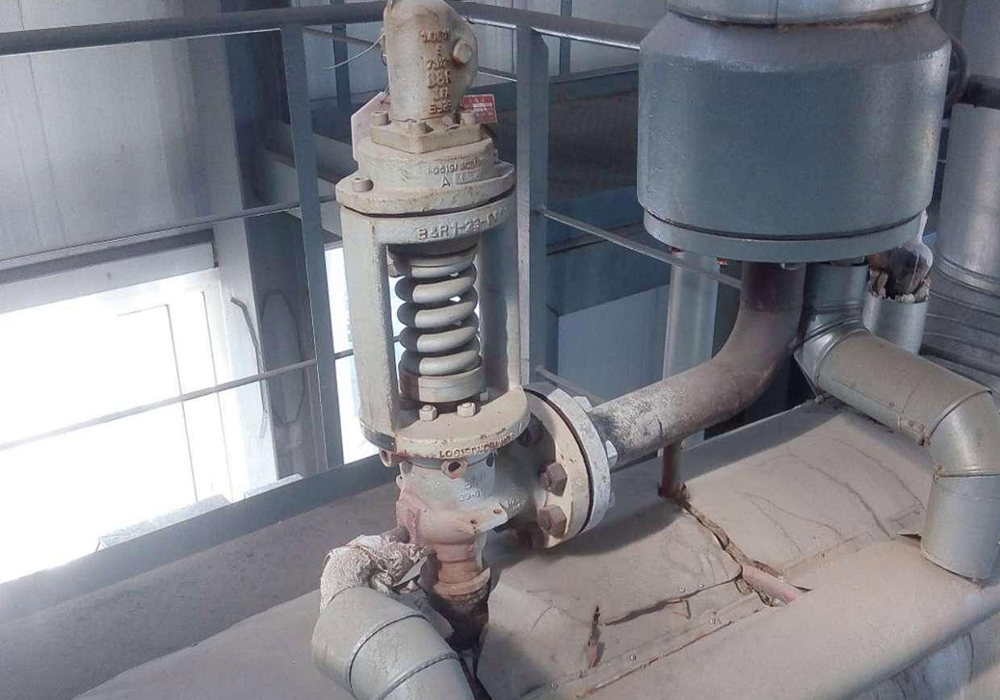

4.1 Spring-Loaded Safety Valve (Most Common)

• Operates via a mechanical spring mechanism.

• The valve opens rapidly and fully when the pressure reaches the set limit.

• Common applications include steam boilers, compressed air systems, and gas systems.

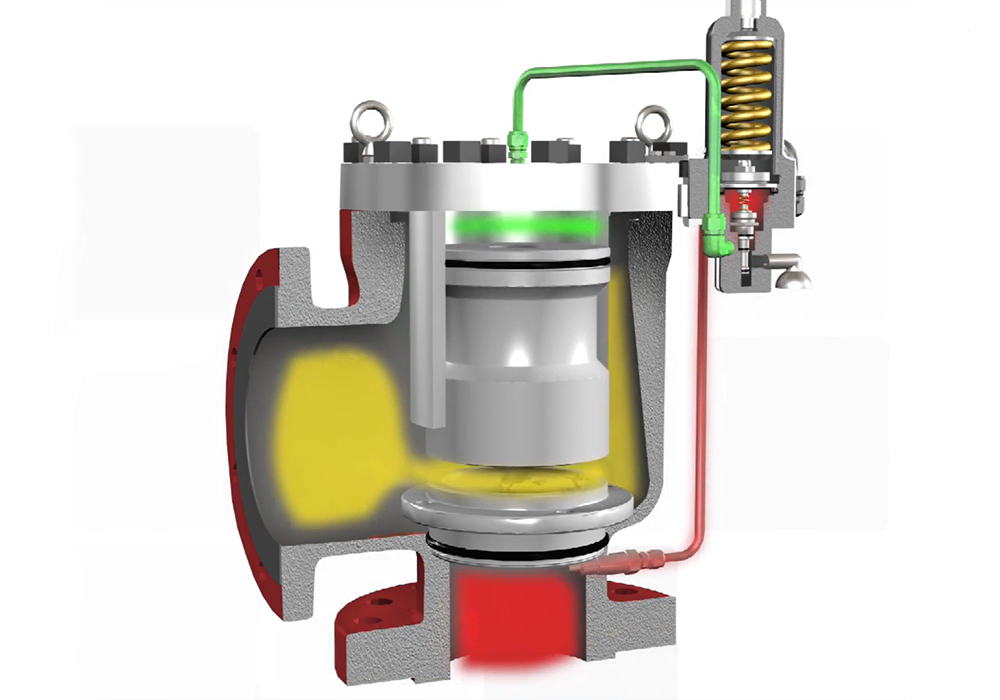

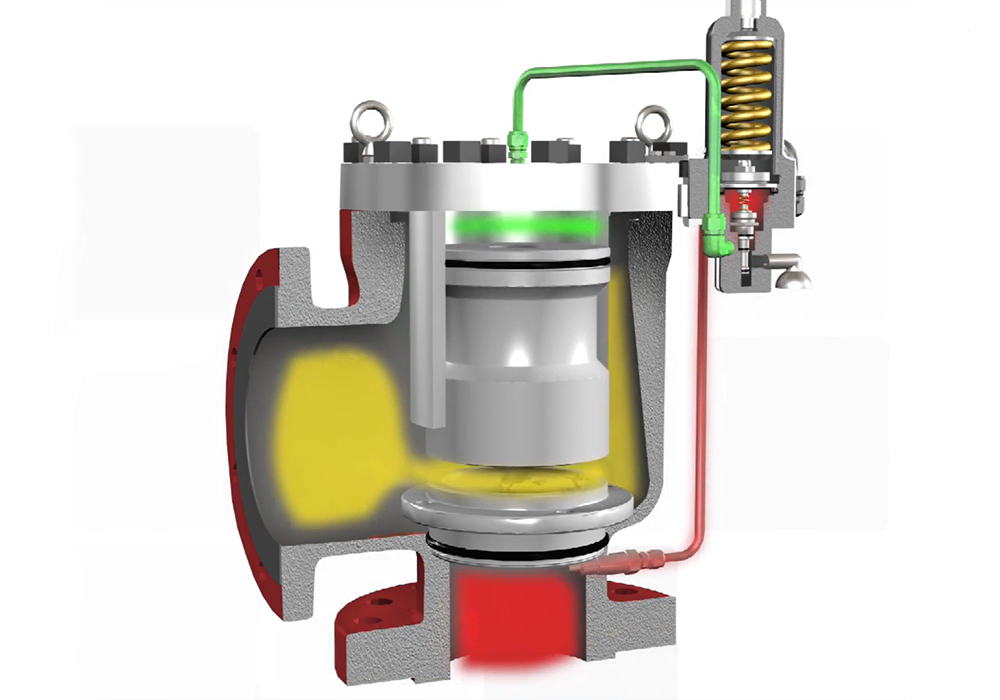

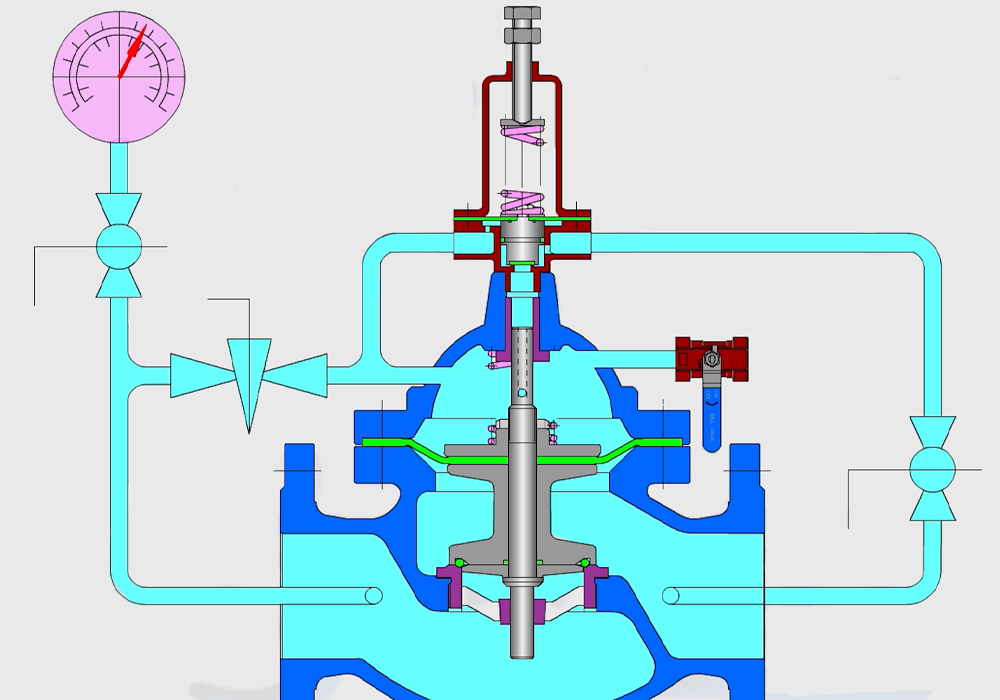

4.2 Pilot-Operated Safety Valve

• Uses a pilot valve to sense pressure and activate the main valve.

• Engineers design these valves to handle extremely high pressures.

• Industries like oil and gas, offshore drilling, and aerospace commonly use them.

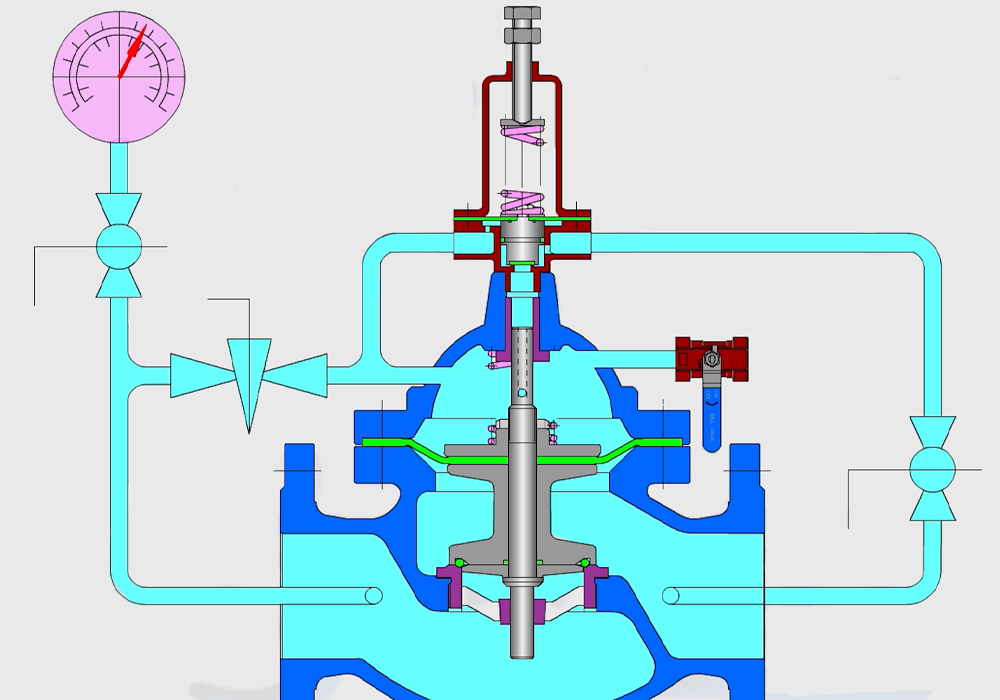

4.3 Balanced Bellows Safety Valve

• Bellows counteract backpressure.

• Minimizes seat leakage and increases accuracy.

• Ideal for complex piping layouts and fluctuating downstream pressure.

4.4 Lever-Type Safety Valve

4.5 Thermal Relief Valve

• Smaller valve for protecting systems from thermal expansion (e.g., liquid trapped in piping).

• Not suitable for large-volume discharge.

4.6 Liquid Service Safety Valve

5. Safety Valve vs Relief Valve: What's the Difference?

A common confusion in the industry is between safety valves and relief valves. While both serve the purpose of overpressure protection, their mechanisms and applications differ.

| Feature | Safety Valve | Relief Valve |

| Medium | Gas / Steam | Liquid |

| Operation | Instantaneous “pop” | Gradual opening |

| Set Pressure | Fixed and precise | Can vary with system dynamics |

| Application | Boilers, compressed gas | Pumps, hydraulic systems |

| Action Type | Quick release | Proportional control |

Pro Tip: If your system handles steam or air under pressure, a safety valve is the correct choice. For pump protection and liquid flow systems, relief valves may be more appropriate.

6. Industrial Applications of Safety Valves

Safety valves are required by law or code in most pressure-related systems. Here are the key industries and use cases:

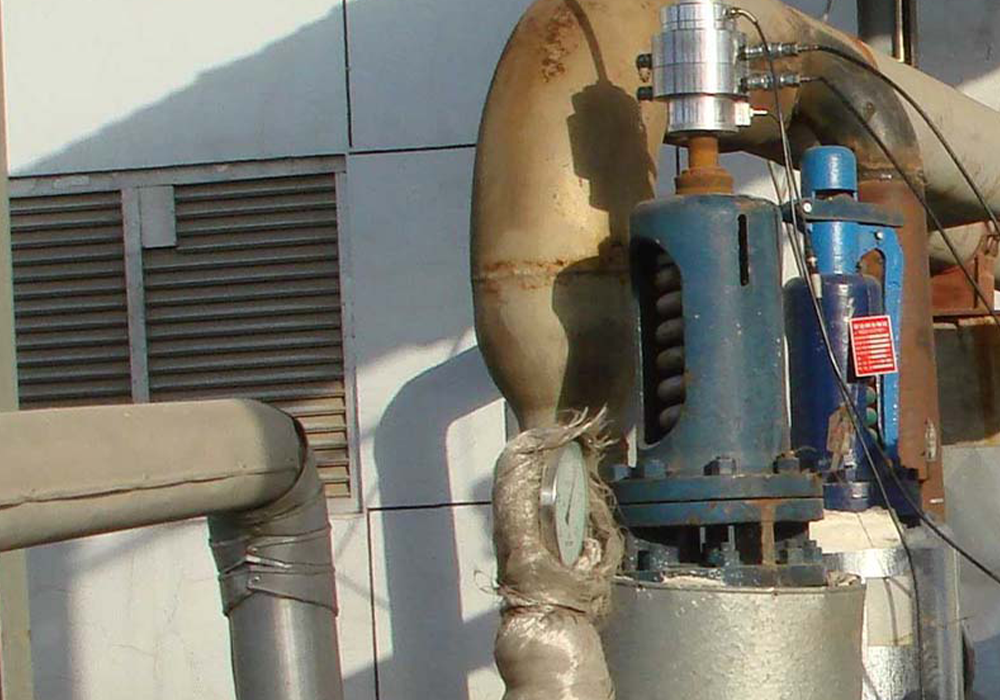

6.1 Power Generation

6.2 Oil & Gas

• Protecting vessels, separators, and compressors from gas overpressure.

• Many industries require API-standard valves.

6.3 Chemical Processing

• Pressure buildup in reactors, autoclaves, and pipelines can be hazardous.

• Materials must be chemically compatible.

6.4 Marine and Offshore

6.5 HVAC and Building Systems

6.6 Food & Beverage and Pharma

7. Safety Valve Standards and Certification

When choosing a safety valve, compliance with standards ensures both performance and legal validity.

7.1 Major Standards

• ASME Boiler and Pressure Vessel Code (Section I and VIII) – USA

• EN ISO 4126 – European Union

• API 520, 526, 527 – Oil & Gas Industry

• PED (Pressure Equipment Directive) – EU compliance

7.2 Manufacturer Responsibilities

As a manufacturer, we ensure:

• Material traceability

• Hydrostatic and functional testing

• Factory set and reseat pressure calibration

• Documentation for audit and traceability

8. Key Factors to Consider When Selecting a Safety Valve

Choosing the right safety valve requires more than just matching pressure ratings.

| Factor | Explanation |

| Set Pressure | Must be below the design pressure of the vessel/system |

| Flow Capacity | Must handle the maximum possible pressure discharge |

| Backpressure | Consider whether the system will experience variable outlet pressure |

| Material | Choose material compatible with your fluid or gas |

| Connections | Threaded, flanged, tri-clamp—depends on system design |

| Certifications | Ensure it meets your industry standards |

9. Why Choose Us as Your Safety Valve Supplier?

As a professional valve manufacturer, we provide complete engineering, customization, and after-sales support for your safety valve needs.

✅ What Sets Us Apart:

• ASME, ISO, CE certified

• Materials: Brass, stainless steel, cast steel, alloy

• Pressure range: 0.2 bar to 400 bar

• Design: Spring-loaded, pilot-operated, balanced bellows, sanitary

• Support: Engineering team + global logistics

• MOQ flexibility for OEMs and MROs

“Designers must carefully design safety; it is not optional.” Allow us to support you in creating the right safety solutions.”

10. FAQ About Safety Valves

Q: Can i reuse safety valves after they have operated?

A: Yes, but they must be tested and resealed according to code. Experts do not advise operating safety valves frequently without proper testing.

Q: What typically causes safety valves to develop leaks?

A: Dirt on the seat, worn spring, improper pressure setting, or backpressure issues.

Q: How regularly should safety valves undergo testing?

A: According to ASME: annually for steam systems; more frequently in critical processes.

Q: What’s the difference between a pressure regulator and a safety valve?

A: Regulators control pressure continuously. Safety valves only activate in emergency overpressure situations.

11. Installation Best Practices for Safety Valves

Proper installation is paramount to the effective operation of safety valves. Adhering to best practices ensures that the valve functions correctly and complies with safety standards.

11.1 Orientation and Positioning

• Vertical Installation: Safety valves should be installed in an upright vertical position to ensure proper operation. Installing them in any other orientation can adversely affect performance and may not meet code requirements.

• Proximity to Equipment: Install the safety valve as close as possible to the equipment or pipeline it protects. This minimizes the potential for pressure drop and ensures rapid response to overpressure situations.

11.2 Piping Considerations

• Inlet and Outlet Piping: The pipe entering the valve should be the same size and as short and straight as possible. The pipe leaving the valve should also match its outlet size and be clear of any blockages so the flow can pass easily.

• Avoiding Turbulence: Make sure to install the valve away from bends, elbows, or other parts that cause water to swirl, so it works smoothly. A recommended practice is to install the valve at least 10 pipe diameters away from any such disturbances.

11.3 Environmental Considerations

• Drainage: In steam systems, place the safety valve above the steam pipe to stop water from building up, which can cause rust and leaks.

• Accessibility: Install the valve in a location that is easily accessible for inspection, testing, and maintenance. This facilitates regular upkeep and ensures timely response in case of valve activation.

12. Maintenance and Inspection Guidelines

Regular maintenance and inspection are critical to ensure the reliability and longevity of safety valves. Neglecting these practices can lead to valve failure, posing safety risks and potential equipment damage.

12.1 Inspection Frequency

• Routine Checks: Conduct regular visual inspections to identify signs of wear, corrosion, or damage. Operators should perform functional testing regularly to make sure the valve opens at the set pressure and closes properly.

• Service Life: The average lifespan of safety valves varies based on materials and operating conditions. For example, valves with rubber seals need new seals every 2 to 3 years. Valves with metal or PTFE seals last about 3 to 4 years.

12.2 Common Issues and Solutions

• Corrosion: Regularly inspect for corrosion, especially in environments with high humidity or corrosive substances. If detected, clean the affected areas and apply appropriate protective coatings.

• Leakage: Leaks can result from debris on the seat, worn seals, or improper installation. Ensure that the system is clean before installation and replace any damaged components promptly.

• Improper Set Pressure: Verify that the valve's set pressure aligns with system requirements. Qualified personnel should make adjustments to keep the system safe.

12.3 Record Keeping

• Maintenance Logs: Maintain detailed records of all inspections, tests, and maintenance activities. This documentation aids in tracking the valve's performance over time and planning future maintenance schedules.

Conclusion

Engineers, buyers, and safety professionals must understand what a safety valve is, how it works, and how to choose the right one. These valves are more than components—they are critical to life safety and equipment integrity.

As a manufacturer focused on innovation and safety, we help you pick the best solution for your system. Explore our catalog, speak to an engineer, or request a quote today.