Video

| | |

| COVNA Electric Butterfly Valve Introduction | COVNA Electric Valve Series |

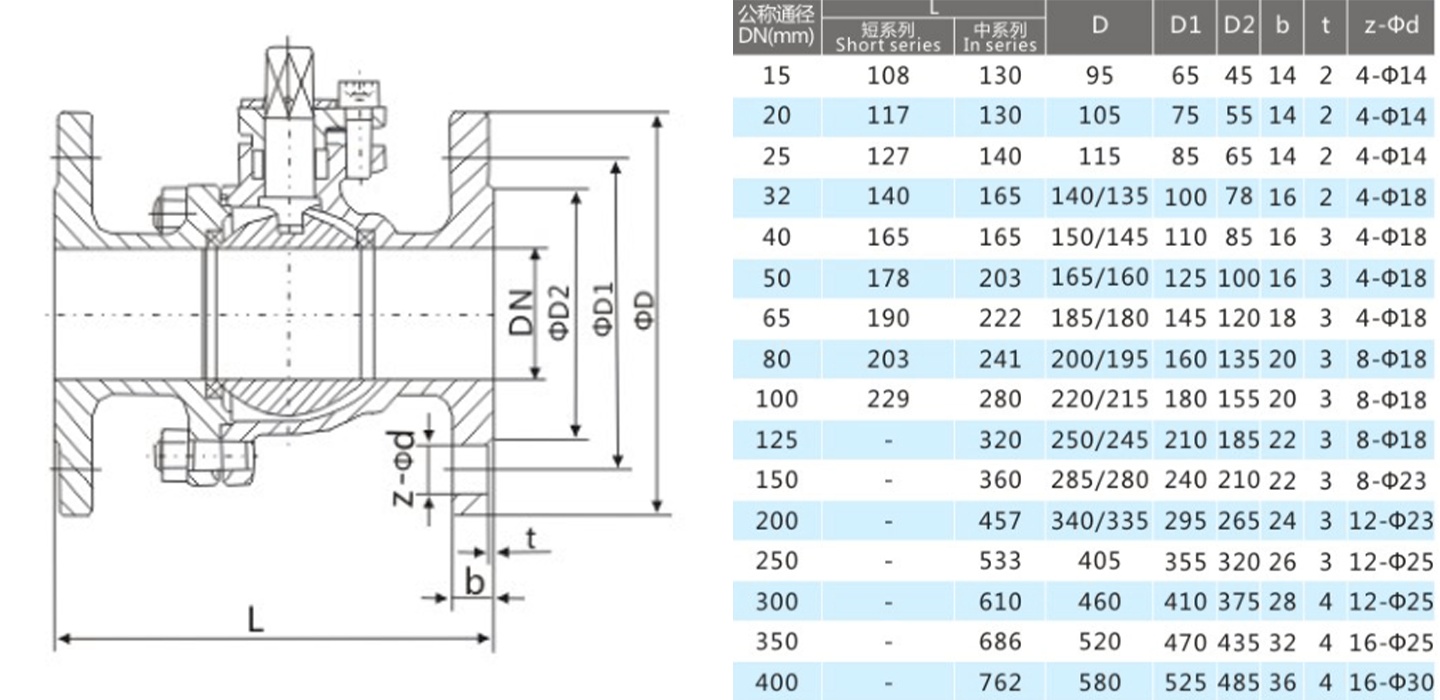

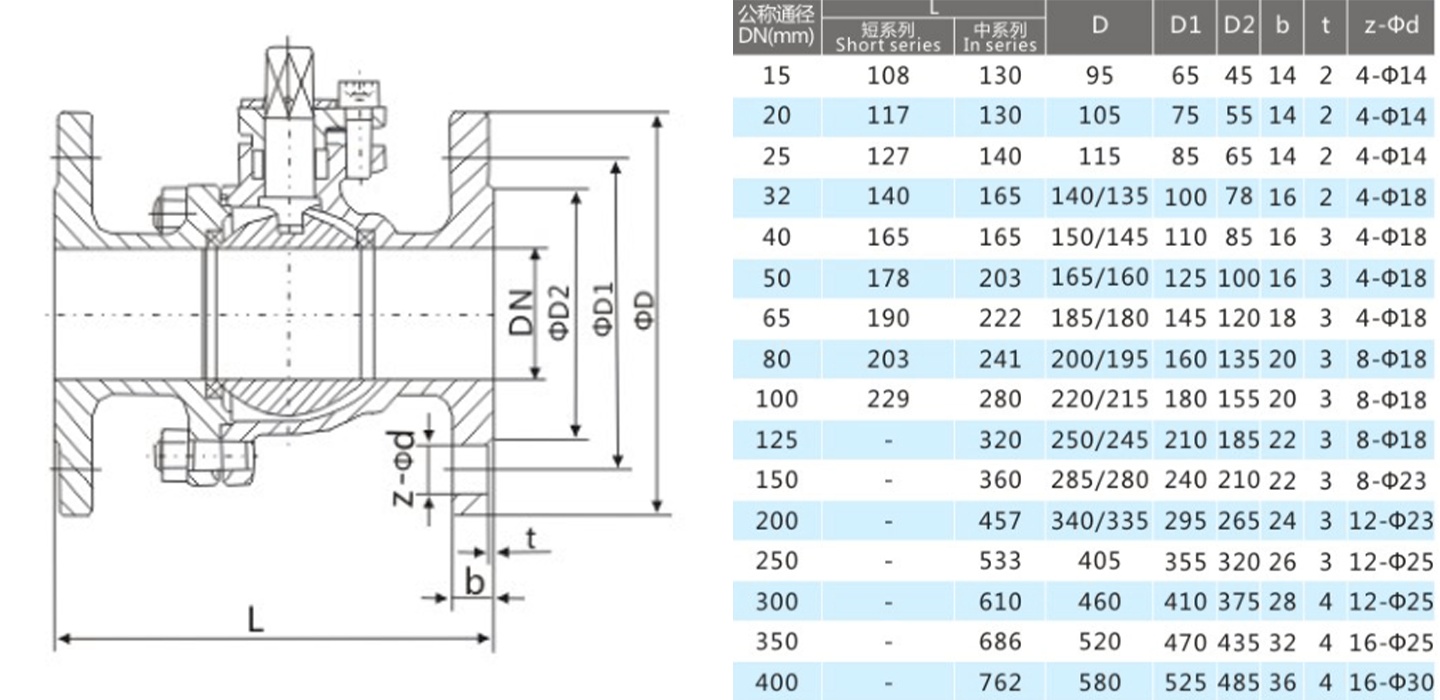

Parameters

Why choose COVNA

1. Contributes to the "Industrial Valve Low-Carbon Standard" and adopts solar-powered facilities, reducing carbon emissions by 27% compared to industry averages.

2. Supplies hydrogen battery valve assemblies to CATL, achieving a pipeline leakage rate reduction to 0.008% for Sinopec, and introduces intelligent wastewater treatment valve systems at the Shanghai Environmental Expo.

3. Operates direct service centers in 12 countries across North America (U.S. division), Europe (Russia office), and Southeast Asia, offering 48-hour emergency response.

4. An office will be established in Russia in December 2024

5. Valves can be manufactured according to your drawings and laser-printed with your company's logo