Video

| |

Employees explain COVNA explosion-proof electric valve | COVNA Solenoid Valve Series |

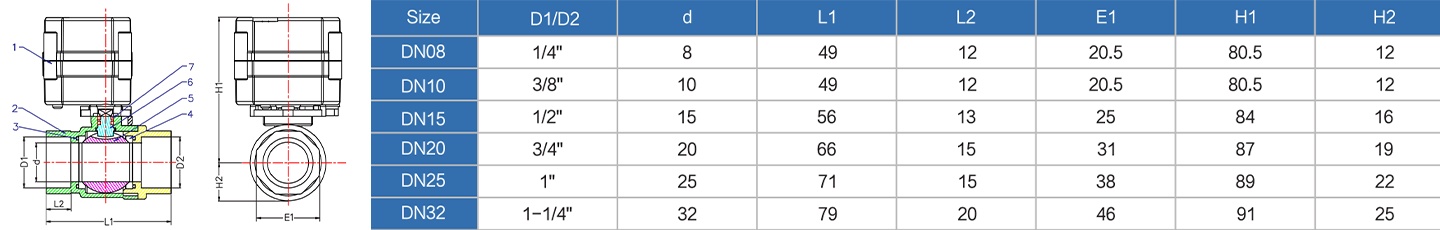

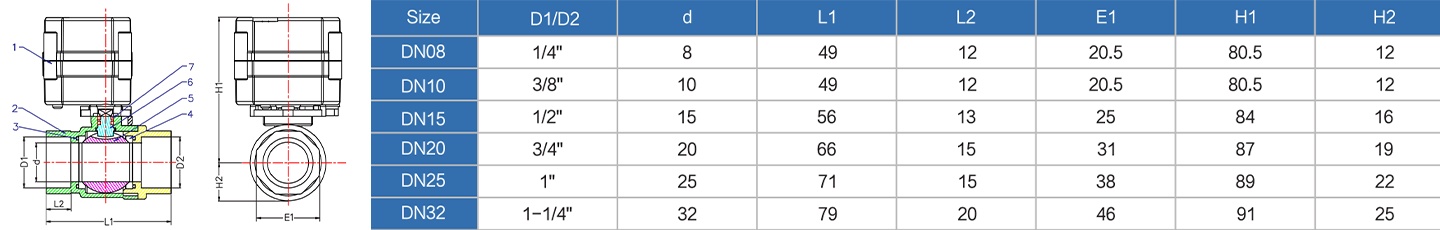

Parameters

Why choose COVNA

1. Comprehensive range: DN15-DN400, materials include cast iron/WCB/stainless steel/plastic, with multi-angle actuators for extreme operating conditions

2. OEM services available: Custom production based on client designs + laser branding solutions

3. Possesses proprietary fluid control valve technologies, including explosion-proof solenoid valves and vacuum equipment-specific valves, with customized hydrogen energy battery valve solutions for the new energy sector.

4. All valve products come with a 5-year quality warranty

5. Over 20 years of manufacturing experience, with products exported to 86 countries/regions and operational in 245 global pilot projects