What is Valve Trim?

In industrial process control, every component inside a valve plays a role, but few are as vital as the valve trim. If you use valves for steam, gas, chemicals, or thick liquids, it’s important to know about valve trim. It helps your system work safely and well for a long time.

This guide teaches you about valve trim — what it is, what makes it up, the different types, how it works, how to choose the right one, and how to take care of it. By the end, you’ll see why good valve trim is key to making valves last longer and work better.

What is Valve Trim?

Valve trim means the inside parts of a valve that touch the fluid and help control, seal, or slow down the flow. These parts are typically subject to wear and corrosion because of pressure, temperature, and the nature of the fluid.

Key Functions of Valve Trim

• Controls the rate and pattern of fluid flow

• Provides sealing against leakage

• Resists erosion and corrosion

• Ensures precise actuation under varying conditions

Components Included in Valve Trim

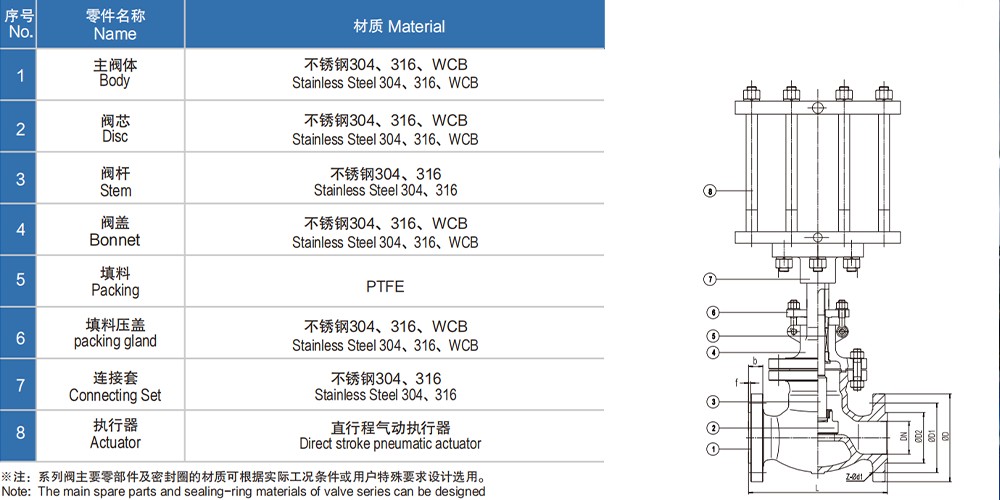

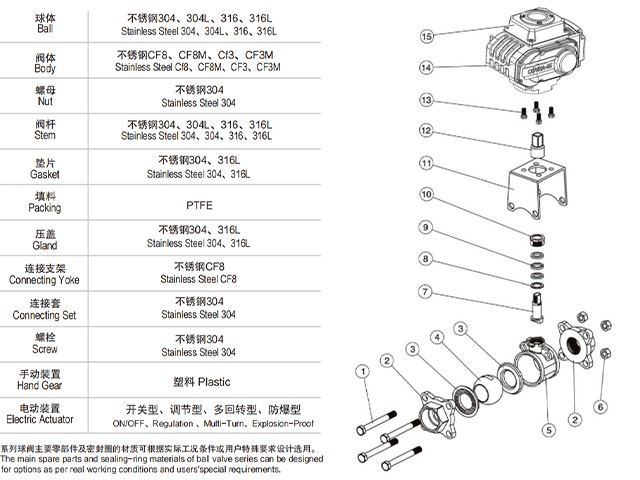

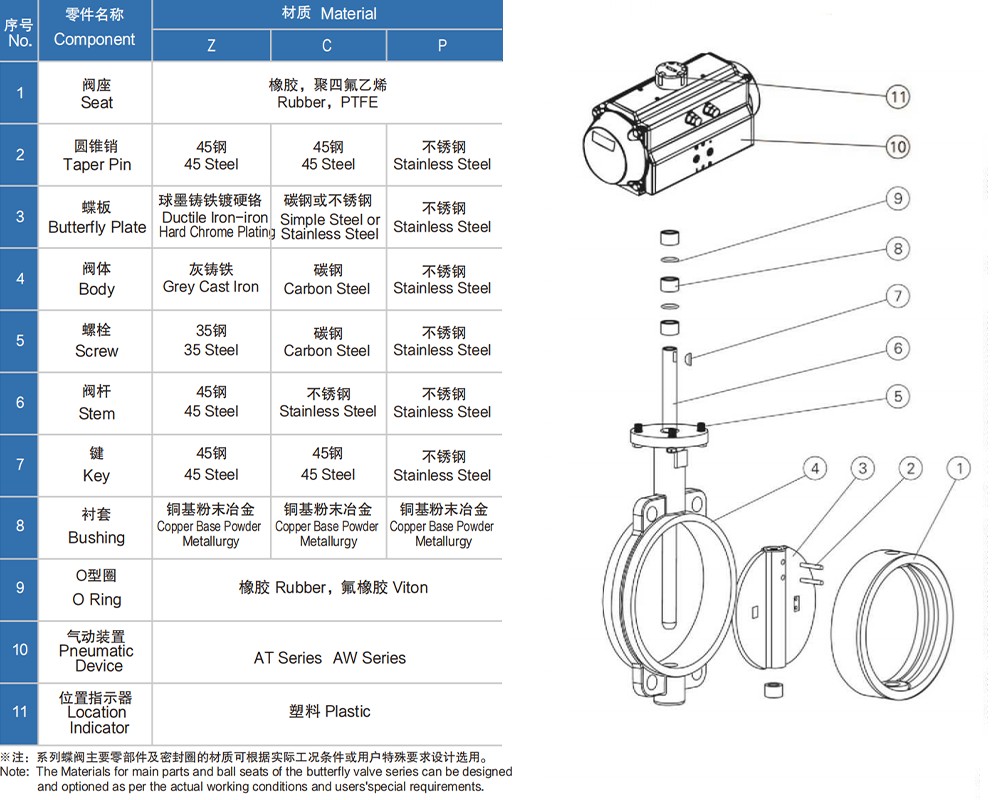

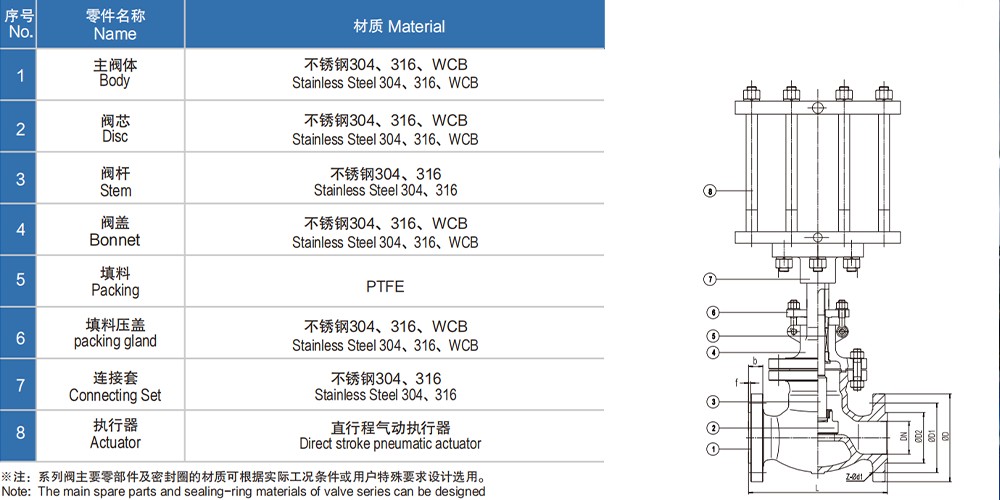

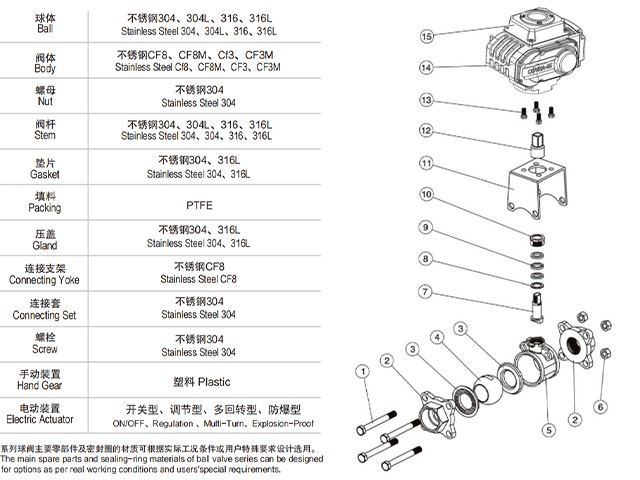

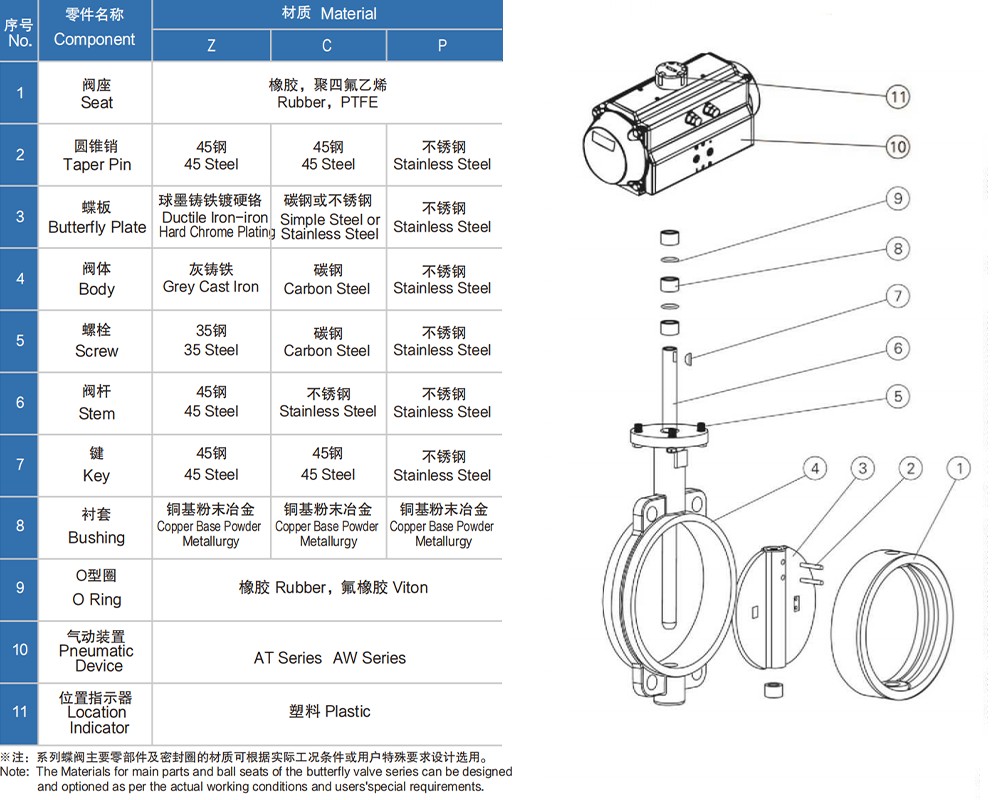

The specific parts that constitute valve trim may vary slightly by valve type (e.g., globe vs. ball), but in general, it includes the following:

| Component | Description |

| Disc/Plug/Ball/Gate | The flow control element that opens/closes against the seat |

| Seat(s) | Surfaces the disc presses against to form a seal |

| Stem | Transfers motion from actuator/handwheel to plug or gate |

| Backseat | Prevents stem leakage in fully open position (mostly in gate valves) |

| Guides and Bushings | Support stem alignment and reduce vibration |

| Packing & Gaskets | Maintain pressure tightness and prevent leakage to atmosphere |

Why Valve Trim is So Critical

The valve body holds everything together and handles pressure, but the trim decides how well the valve works and lasts over time.Here's why trim deserves special attention:

1. Flow Accuracy

Trim shape and geometry influence how the valve modulates flow — critical in process control loops.

2. Material Compatibility

If the process fluid doesn’t match the trim material, corrosion or erosion can cause the trim to fail early.

3. Maintenance Cost

Trims are typically the first components to wear out. Poor-quality trims require frequent replacement.

4. Pressure and Temperature Resistance

Trim must maintain integrity and sealing across wide ranges of operating conditions.

Flow Characteristics Defined by Trim

Engineers design each trim to create a specific flow pattern — how the flow changes as the valve opens.

Types of Flow Characteristics:

• Linear: Flow changes at a constant rate as valve opens (ideal for certain pressure conditions)

• Equal Percentage: Small changes in opening yield increasingly large flow changes (commonly used in control valves)

• Quick Opening: Maximum flow is achieved quickly; best for on/off applications

Choosing the wrong trim characteristic can result in unstable process control, pressure surges, or cavitation.

Common Valve Trim Materials

Trim material selection is a crucial part of valve engineering. Factors include chemical compatibility, wear resistance, and cost. The API made some common trim types (like No. 5, 8, and 9) to help you pick the right one more easily.

Standard Trim Materials:

| Material | Properties | Application |

| 410 SS | Hardenable stainless steel; basic corrosion resistance | Water, steam, air |

| 316 SS | Excellent corrosion resistance | Acids, seawater, chemicals |

| Monel | Nickel-copper alloy; very corrosion resistant | Saltwater, hydrofluoric acid |

| Hastelloy | Highly resistant to strong oxidizers | Harsh chemical environments |

| Stellite | Cobalt alloy; excellent wear and erosion resistance | Severe service |

| Tungsten Carbide | Extremely hard, ideal for slurry or abrasive flow | Mining, pulp & paper |

Trim Classification: API Trim Numbers

To standardize trim combinations, API 600 introduced a numbering system:

• Trim 1: 410 SS seat and disc

• Trim 5: Hard-faced seat and disc with 410 SS base

• Trim 9: Monel disc and seat

Always verify API trim compatibility with fluid and pressure conditions before ordering.

Types of Valve Trim (By Design)

Valve trim can be designed to meet different performance needs:

1. Single-Stage Trim

Used in moderate pressure drop applications. Provides basic throttling.

2. Multi-Stage (Pressure Letdown) Trim

Used in high-pressure systems to reduce cavitation and noise by dissipating energy in stages.

3. Anti-Cavitation Trim

Engineered to prevent vapor bubble formation — vital in water and liquid services.

4. Low-Noise Trim

Reduces aerodynamic noise in high-pressure gas or steam flow.

Each of these designs increases performance and lifespan in challenging environments.

When to Use Special Trim?

If your process involves:

• High ΔP (pressure drop)

• Flashing or cavitation risk

• Noise limitations (e.g., power plants)

• Abrasive or corrosive fluid

Then custom-engineered valve trim is not a luxury — it’s a necessity.

How to Select the Right Valve Trim

Selecting the correct valve trim involves a balance of:

• Process fluid chemistry (is it acidic, basic, salty, particulate-heavy?)

• Operating pressure and temperature

• Flow control requirements (accuracy vs. simplicity)

• Industry standards (API, ASME, ANSI, NACE)

• Maintenance preferences (ease of replacement)

We recommend you ask a valve expert to check your system and help pick the best trim for you.

Valve Trim Maintenance Tips

Even the highest-quality trims will eventually wear out. Follow these maintenance practices:

• Periodic Inspection: Especially in severe service, inspect trim every 6–12 months

• Replace Sealing Surfaces: Seats and discs are most prone to wear

• Avoid Improvised Repairs: Use OEM trim kits to avoid seal mismatches

• Document Service History: Helps predict wear patterns and plan replacements

Modern valves often come with quick-change trim kits that reduce downtime.

The Hidden Cost of Poor Trim

A valve may be inexpensive, but if the trim fails early or causes instability, the cost of:

can far outweigh the price difference of choosing high-quality trim upfront.

Future Trends in Valve Trim Technology

As industrial processes become more complex and regulated, valve trim technology is evolving to meet new challenges. Digitalization and Industry 4.0 trends are bringing smart diagnostics and condition monitoring to valve internals. Engineers add new sensors to trims to monitor wear, damage, and flow in real time.

Additive manufacturing (3D printing) is changing how engineers design and make custom trims. By layering specialized alloys, manufacturers can now create highly intricate trim geometries that previously would have been too costly or impossible using traditional machining.

These innovations promise longer trim life, improved accuracy, and reduced downtime. When you need valves for a new project or to fix your plant, choose a company like us with new trim and tools.

Industry Standards and Regulatory Compliance

In places like oil plants or power stations, valve trim helps valves work right and keeps things safe.

Trim must often comply with:

• API 600, 602, 623, or 6D

• NACE MR0175/ISO 15156 for sour gas service

• ASME B16.34 pressure-temperature ratings

• Fugitive emissions certifications (ISO 15848, EPA 40 CFR Part 60)

Failure to comply with these standards can result in fines, environmental risks, or even catastrophic system failures. We make and test our valves to meet global standards. We provide full material records and third-party test reports to help with your project needs.

Why Choose Our Valves?

As a global valve manufacturer with decades of experience, we don't cut corners on valve trim. Here's what sets us apart:

✅ API and ANSI Standard Compliance

✅ Precision-machined trims for leak-tight shutoff

✅ Specialty materials for severe services

✅ Custom trim available for OEMs and EPCs

✅ Field-replaceable designs to reduce downtime

We help clients in oil & gas, chemical, water treatment, marine, and power industries choose the right valve + trim package for their exact needs.

Final Thoughts

The next time you’re evaluating or purchasing a valve, remember:

The body holds the pressure, but the trim controls the performance.

Trim selection affects flow accuracy, seal integrity, lifespan, noise, safety, and cost. Learn about valve trim and choose a maker who builds carefully. This gives you better control, fewer issues, and peace of mind.

Are you prepared to improve your valve performance?

Contact us today for a quote, a consultation, or a sample of our engineered valve trims.