What Is a Pressure Release Valve?

When pressure builds up too much, this valve releases it to stop problems. As a professional valve manufacturer, we understand the essential role these valves play in system safety and stability.

This guide will show you what a pressure release valve is, how it works, where you’ll find it, and how to choose the best one

What Does a Pressure Release Valve Do?

The valve opens by itself when the pressure in the system gets too high. Its job is simple but crucial: it lets out extra pressure to stop damage or accidents.

When the pressure goes back to a safe level, the valve closes again. This helps the system keep running smoothly and safely.

Why Are Pressure Release Valves Important?

People must control pressure, from home heating systems to large industrial setups. Without a pressure release valve, pressure can build up to dangerous levels. Here’s what could happen without proper protection:

• Boiler explosions in domestic heating systems

• Cracked pipes or leaking seals in industrial pipelines

• Damage to pumps, compressors, or storage tanks

• Risk to human safety and property

A good pressure release valve keeps your system safe by controlling pressure, so you don’t have to worry and can avoid expensive repairs.

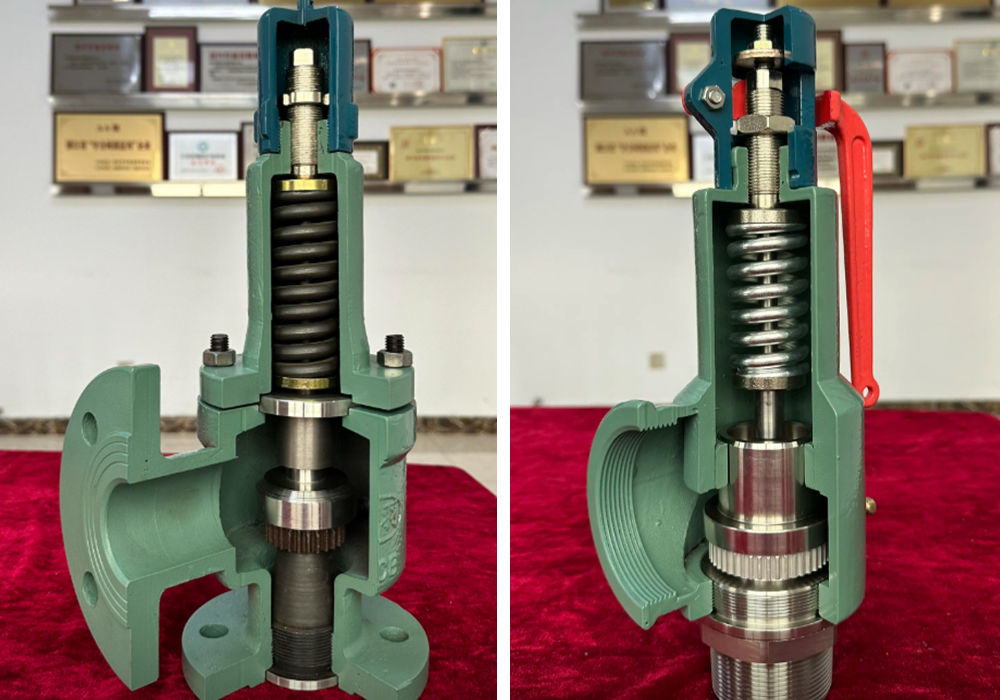

How Does a Pressure Release Valve Work?

Let's break it down into simple steps:

• System Pressure Increases

As the pressure inside the system rises (because of heat, flow, or blockages), it approaches the valve’s setpoint.

• Valve Activation

When the pressure goes over the set limit, the valve opens—usually by pushing down a spring or moving a diaphragm. This permits the controlled release of fluid, whether gas or liquid.

• Pressure Drops

The release of fluid reduces internal pressure.

• Valve Closes

Once pressure returns to a safe level, the spring or diaphragm pushes the valve shut.

This automatic cycle helps systems maintain optimal operation while preventing hazards.

Where Are Pressure Release Valves Used?

Pressure release valves are used in:

• Home heating systems (boilers)

• Compressed air systems

• Pneumatic and hydraulic equipment

• Chemical processing plants

• Oil and gas pipelines

• Food and pharmaceutical production

• Aerospace and defense systems

Each application requires a specific type of valve—ranging in materials, response sensitivity, and pressure range.

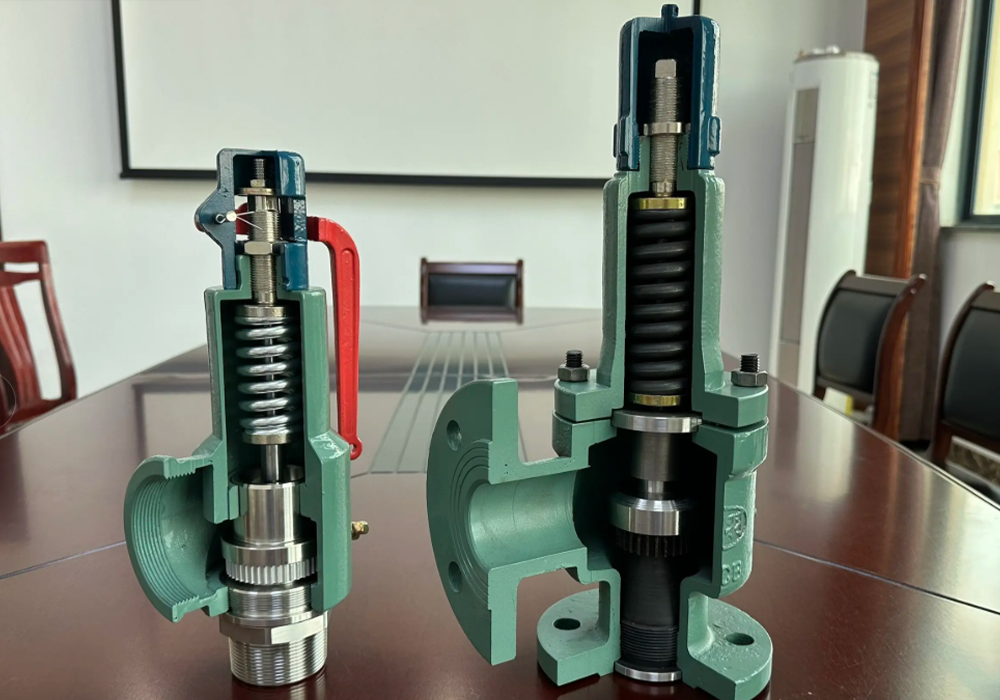

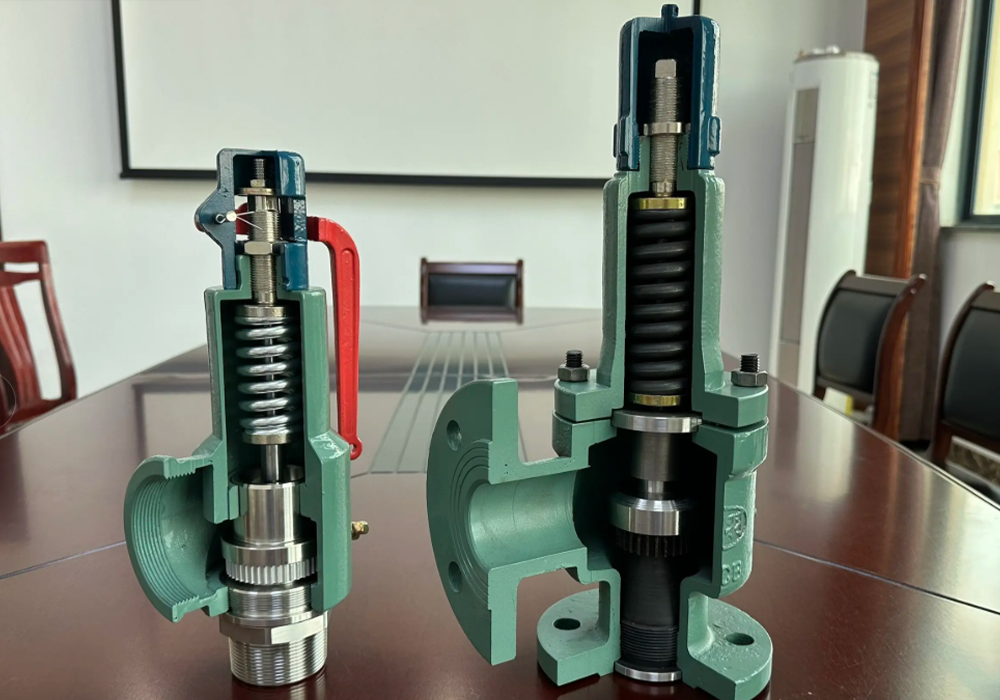

Types of Pressure Release Valves

Several types exist, but the most common include:

• Spring-loaded pressure relief valves: Use a spring to hold the valve closed until the set pressure is reached.

• Pilot-operated relief valves: Use system pressure to control the valve operation for higher accuracy and larger flow capacities.

• Thermal relief valves: Specifically respond to heat-induced pressure increases in liquids.

• Vacuum relief valves: Allow air into a system when pressure drops below atmospheric pressure.

Choosing the correct type is crucial for both performance and safety.

Common Pressure Relief Valve Problems (and How to Avoid Them)

Household PRVs can develop issues like:

• Continuous leaking (may signal debris or worn seals)

• Corrosion from poor material compatibility

• Blockage because of mineral build-up or poor maintenance

For industrial users, problems may stem from:

Solution: Work with a trusted valve manufacturer who provides technical support, custom specifications, and robust quality control.

How to Choose the Right Pressure Release Valve

Here's a quick checklist:

• ✅ Know your system’s max operating pressure

• ✅ Determine the required set pressure

• ✅ Define the medium (liquid, steam, gas, corrosive fluid, etc.)

• ✅ Choose appropriate materials (brass, stainless steel, polymer)

• ✅ Consider flow rate and discharge capacity

• ✅ Verify industry certifications (ISO, CE, ASME)

Common Applications of Pressure Release Valves

Pressure release valves play a crucial role across many different industries and settings. In residential homes, they are most commonly found in heating systems like boilers and water heaters. They stop pressure from getting too high. This keeps the equipment safe and protects the household.

Pressure release valves are important in many industries. These include oil and gas, chemical processing, power generation, and manufacturing. In these settings, the valves protect pipelines, tanks, compressors, and other equipment.

They handle gases or liquids under high pressure. By automatically releasing extra pressure, they prevent expensive damage and downtime. This helps avoid serious failures and keeps operations safe and efficient.

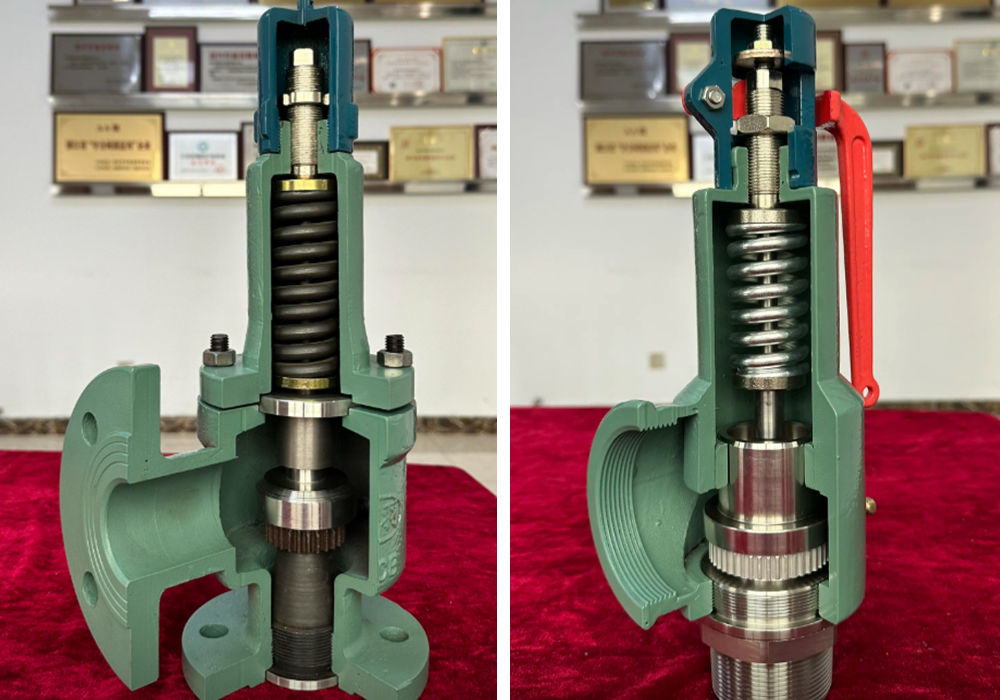

Key Features to Consider When Choosing a Pressure Release Valve

Choosing the right pressure release valve requires careful consideration of several important features. First, the quality of materials is important.

Valves made from stainless steel or brass resist corrosion and wear better. This is especially true in tough environments. Next, the valve’s pressure rating and setpoint must match the specific needs of your system to ensure it activates at the right time.

Thinking about how fast the valve responds and how well it seals is important. A quick and tight seal stops leaks and makes things safer. Some valves offer adjustable setpoints, allowing fine-tuning based on system requirements.

Certifications like ASME, ISO, or PED show that the valve meets safety and quality industry standards. Finally, you should consider ease of installation and maintenance to reduce downtime and operational costs.

Importance of Regular Maintenance and Testing

Maintaining and testing your pressure release valves regularly is key to ensuring their reliable operation over time. Valves can work less effectively because of mineral buildup, rust, or wear. This is common in systems that handle water or corrosive fluids.

Routine inspections help identify signs of damage or blockage early. Cleaning and servicing valves as recommended by manufacturers can restore proper function and extend their service life. We need to conduct periodic testing to ensure the valve opens at the right pressure. This keeps the system safe and meets regulations.

Neglecting maintenance can cause valve failure. This puts equipment and people at risk. It can also lead to costly repairs or shutdowns. Investing in regular upkeep protects your system and maximizes the value of your pressure release valves.

Why Buy Pressure Release Valves from Us?

As an experienced valve manufacturer, we offer:

✔ Precision-engineered PRVs for all industries

✔ Custom pressure settings and materials

✔ Fast lead times and global shipping

✔ ISO-certified production and QC systems

✔ Expert support for system design and maintenance

Conclusion

What is a pressure release valve? In short, it’s a safety valve that keeps your system running safely and efficiently by releasing excess pressure. No matter if it’s a home boiler or an industrial plant, having the right valve is a must.

Need help selecting the right pressure release valve for your system?

[Contact our engineering team now]