What Is a Control Valve?

In modern industrial processes, precise control over fluid flow, pressure, and temperature is crucial for maintaining product quality, safety, and operational efficiency. One of the essential components enabling this precision is a specialized valve designed to regulate fluid dynamics automatically. But what exactly does this device do, how does it operate, and why should you choose the right supplier for it? This detailed guide will answer these questions and help you understand the vital role these valves play in countless industries.

Understanding the Role of Automated Flow Regulators

This kind of valve controls how much fluid—like liquids, gases, or steam—flows through pipes and equipment. Normal valves are either open or closed. This valve can open a little or close a little to control the flow exactly, based on signals it gets.

How It Works

This equipment comprises several key parts:

• Valve Body and Inside Parts: The main part lets the fluid flow through. Inside, parts such as plugs or discs adjust the flow of fluid.

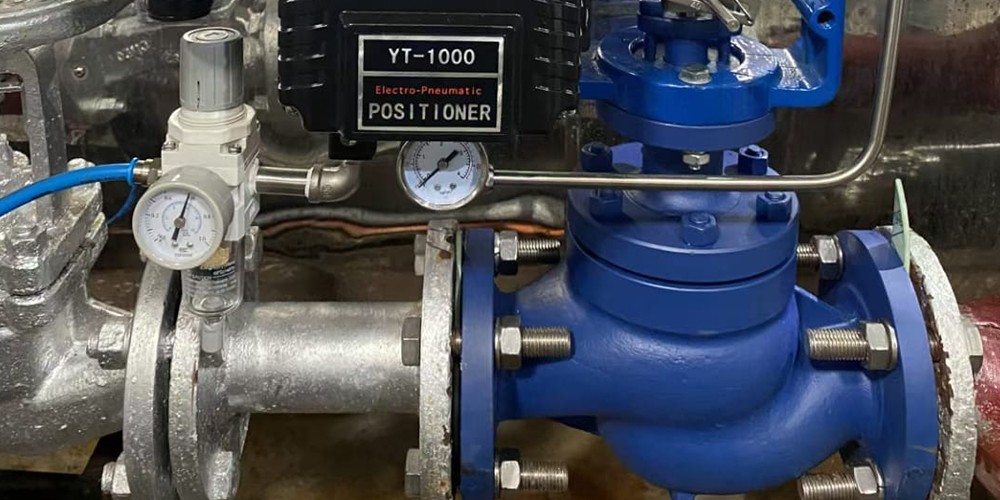

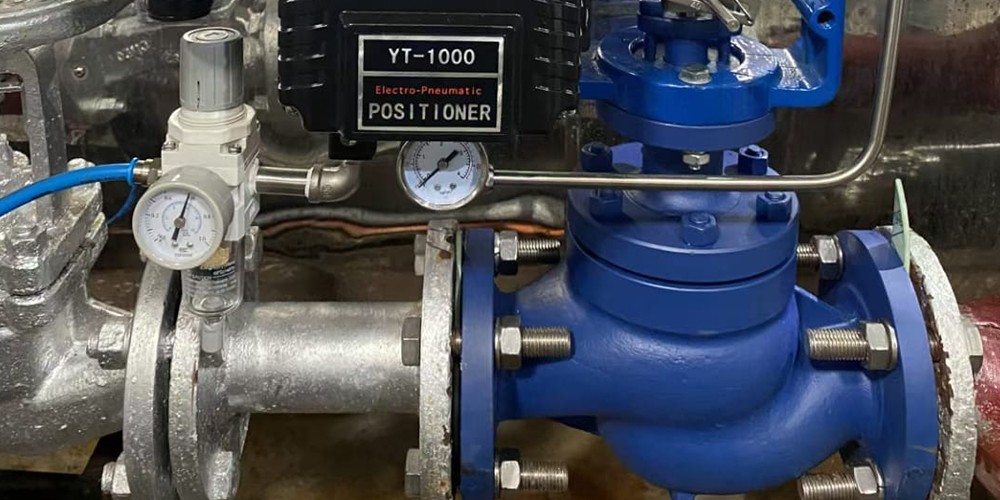

• The Actuator: This mechanism drives the internal parts to move, responding to signals from controllers. Air (pneumatic), electricity, or hydraulic pressure powers the actuators.

• Positioners and controllers: make sure the valve opens just right. Positioners and controllers actively monitor the valve’s position and adjust it immediately when needed.

When the system sends a signal about pressure or flow, the actuator moves the inside parts to adjust the flow. This continuous modulation allows real-time control of process parameters, ensuring the system operates within optimal ranges.

Varieties and Designs to Suit Every Need

Different applications demand different designs, each offering unique benefits:

• Globe Valves

Recognized for their precise throttling ability, globe-type regulators are widely used in processes that require accurate flow control. Their construction allows for smooth and steady adjustment, minimizing turbulence and wear.

• Ball Valves

These devices feature a spherical disc that rotates to open or close the fluid path. Ball valves are strong and seal well. People often use them when they need to quickly stop the flow or control it at medium levels.

• Butterfly Valves

Lightweight and compact, butterfly valves use a rotating disc to regulate flow. They are especially suitable for larger pipe diameters where space and weight are concerns. Their simple design makes them cost-effective and easy to maintain.

• Diaphragm Valves

Designed for corrosive or sanitary environments, diaphragm valves isolate the fluid from mechanical parts by using a flexible membrane. Medicine, food processing, and chemical companies often use them to avoid Unwanted substances.

• Special Designs

People use pinch, needle, and segmented ball valves for different tasks based on the fluid and how they want to control it.

Importance in Industrial Systems

The presence of these flow regulators is vital across industries for several reasons:

• Maintaining Consistent Product Quality

By carefully controlling fluid parameters, these devices keep processes steady, reducing changes in product quality. For example, in chemical manufacturing, exact flow rates and pressures prevent unwanted reactions or impurities.

• Enhancing Operational Safety

Incorrect fluid flow or pressure can cause dangerous too much pressure, equipment damage, or hazardous leaks. Automated valves minimize human error by responding quickly to changing conditions, protecting personnel and assets.

• Improving Energy Efficiency

Optimized flow control reduces unnecessary energy consumption, cutting operational costs. For instance, in power plants, precise steam flow regulation prevents energy waste and equipment wear.

• Enabling Automation and Remote Control

Integration with modern control systems allows operators to monitor and adjust valves remotely, helping complex automated processes that would be impossible to manage manually.

Typical Applications

These valves are essential in sectors such as:

• Oil and Gas: Regulating flow and pressure in pipelines, refineries, and drilling operations.

• Power Generation: Controlling steam, cooling water, and fuel gas flows.

• Chemical Industry: Metering chemical feedstock and managing reaction conditions.

• Water and Wastewater Treatment: Managing filtration rates, chemical dosing, and system pressures.

• Medical and Food Processing: Maintaining hygienic and precise fluid control.

Key Factors When Selecting Your Valves

Choosing the right supplier is as critical as selecting the right product. Here are some factors you should consider:

• Quality and Materials

Industrial fluids vary widely in harshness, temperature, and pressure. Strong metals like stainless steel make the valve body and inside parts last longer and work better.

• Personalization and Flexibility

No two processes are identical. When you need a valve in a certain size or style, a good manufacturer can make one that fits exactly what you need.

• Technical Expertise and Support

Proper installation, calibration, and maintenance are vital for optimal performance. Suppliers with deep industry experience offer valuable technical support, training, and after-sales service.

• Certifications and Standards Compliance

Make sure the valves follow important rules and standards, like API, ANSI, ISO, or others that matter for your industry.

Why Partner With Us?

We make high-quality flow control equipment by using good engineering and industry knowledge to solve your hardest problems.

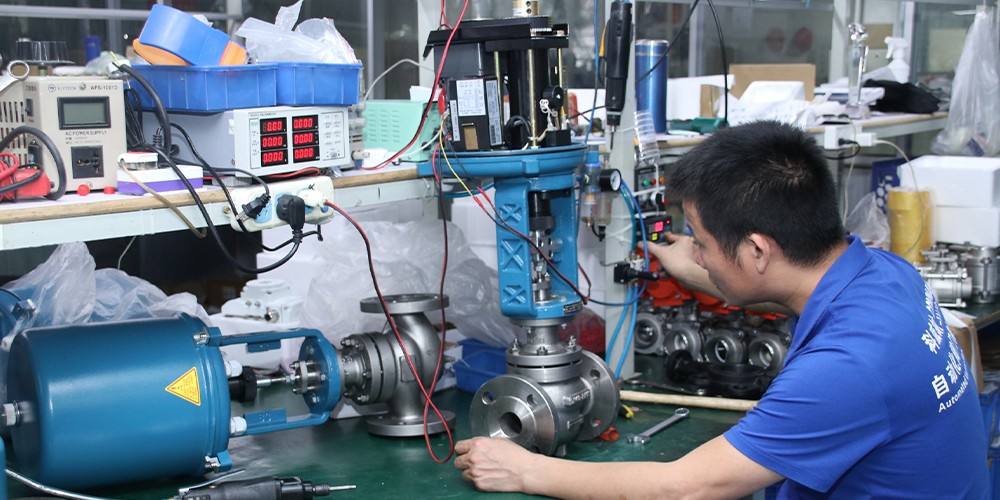

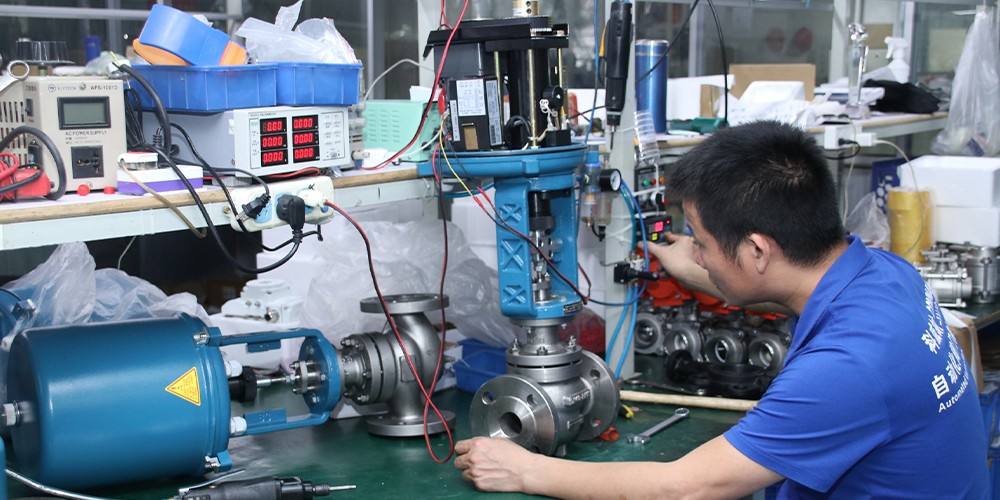

• Advanced Manufacturing: Our valves undergo rigorous testing to guarantee performance under demanding conditions.

• Material Excellence: We source premium alloys and composites tailored to your application needs.

• Innovative Designs: Our engineering team constantly develops solutions that improve efficiency and reduce downtime.

• Customer-Centric Service: From consultation to after-sales, we provide comprehensive support to ensure your satisfaction.

Maintenance and Troubleshooting Tips

Even the best-designed valves require regular inspection and upkeep:

• Routine Visual Checks: Look for leaks, corrosion, or unusual noises.

• Calibration: Verify actuator response and positioner accuracy.

• Cleaning: Remove buildup that could hinder valve movement.

• Replace Worn Parts: Timely replacement of seals, diaphragms, or seats prolongs valve life.

Proper maintenance not only enhances safety and efficiency but also reduces unexpected downtime.

Conclusion

Knowing how automated flow control devices work and how they affect your operation helps you choose the right ones. If you run a refinery, power plant, chemical plant, or water treatment, a good valve helps your system stay safe and work well.

If you are looking for tailored solutions backed by expert knowledge and quality manufacturing, reach out to us. Together, we can optimize your fluid control systems and support your business growth.