What Is WOG Valve?

If you're sourcing valves for water, oil, or gas systems, you may have seen the term "WOG" stamped on ball valves or product catalogs. So, what exactly does a “WOG valve” refer to — and what should you pay attention to when choosing the right one for your system? This article will walk you through the full meaning, usage, and safety considerations of WOG valves.

As a professional valve manufacturer, we take pride in delivering reliable products. Just as importantly, we help you understand the key specifications that ensure those products perform as expected.

✅ What Does "WOG" Mean on a Valve?

The term “WOG” is an acronym representing Water, Oil, and Gas. It shows the highest pressure a valve can safely handle at normal room temperature, usually about 100°F or 38°C.This rating tells you how much pressure the valve can hold without damage when used with water, oil, or gas under steady, constant conditions.

For example, a valve marked 600 WOG can work safely at pressures up to 600 PSI with water, oil, or gas at room temperature.

This means the valve can maintain its integrity under that pressure. Leakage and failure do not occur during normal operation.

Understanding WOG as a Pressure Rating

A WOG rating does not refer to a specific material or valve type. Instead, it is a pressure classification commonly found on many different types of valves, especially including:

• Ball valves

• Gate valves

• Globe valves

• Check valves

Key points:

• WOG = Non-shock cold working pressure

• Unit: PSI (pounds per square inch)

• Mediums: Water, Oil, Non-combustible Gases

• Temp: Room temperature (typically 100°F / 38°C)

WOG vs CWP vs WSP — What’s the Difference?

One of the most common sources of confusion is the difference between WOG, CWP, and WSP ratings. Let’s break it down:

| Term | Full Form | Application | Temperature | Common On |

| WOG | Water-Oil-Gas | Non-shock pressure rating for standard media | 100°F | Ball valves, brass valves |

| CWP | Cold Working Pressure | Same as WOG but used in newer standards | 100°F | Modern valves |

| WSP | Working Steam Pressure | Pressure rating for steam applications | Higher temps | Steam valves, industrial |

Tip: Today, CWP is often used interchangeably with WOG, especially in North America.

Where Are WOG Valves Used?

People commonly use valves with a WOG rating in residential, commercial, and light industrial settings. They are suitable for applications with moderate pressure and non-corrosive fluids.

Typical uses:

Not recommended for:

⚠️ Limitations of WOG Valves

While WOG valves are cost-effective and reliable, there are important safety limitations to keep in mind:

• WOG ratings do not apply to steam. Always verify the WSP rating when you intend to use the valve for steam service.

• WOG only applies at room temperature. Higher temperatures can drastically reduce pressure tolerance.

• Not always suitable for combustible gases. Verify valve certifications when using with flammable media.

Using WOG-rated valves in high-temperature conditions can cause leaks. Sudden pressure shocks may also lead to valve rupture.

How Is WOG Rating Tested on Valves?

The WOG pressure rating is not an arbitrary number. Standardized pressure tests following ANSI/ASME or API guidelines determine it. During these tests, manufacturers apply hydrostatic pressure to the valve. The pressure is between 1.5 and 2 times the valve’s rated limit and uses water at room temperature.

These tests:

• Verify the mechanical integrity of the valve body

• Ensure zero visible leakage from stem seals or end connections

• Confirm seat sealing performance

WOG tests are non-destructive, meaning the valve is still usable after the test if it passes. For valves used in critical applications (like natural gas), technicians may also perform additional air or helium leak tests.

⚠️ Common Myths About WOG Valves — Debunked

1. "WOG indicates the valve is suitable for all gases."

Not necessarily. WOG includes non-combustible gases only. For flammable or explosive gases, authorities often require additional certifications.

2. "A greater WOG rating indicates superior quality."

Not always. A higher rating means more pressure tolerance, but it doesn’t guarantee corrosion resistance, chemical compatibility, or long lifespan. You must consider the application, material, and environmental conditions.

3. "WOG valves are appropriate for steam systems."

Absolutely false. Steam has much higher energy and temperature than the design specifications for WOG valves allow. You must use WSP-rated or steam-certified valves for those applications.

5 Key Factors When Choosing a WOG-Rated Valve

When selecting a WOG valve, don't just look at the number — consider these five essential factors:

• Pressure Rating (PSI)

Match the WOG rating with your system’s operating pressure + safety margin.

• Material Compatibility

Brass, stainless steel, PVC — each has different corrosion and temperature resistance.

• Connection Type

NPT, socket weld, flange — choose based on piping setup and maintenance needs.

• Application Fluid

Even within “oil” or “gas,” compositions vary — ensure chemical compatibility.

• Certification & Compliance

Especially for industrial or regulated environments (UL, FM, CE, ISO, NSF, etc.).

Our company provides expert help and technical support. We can assist you in choosing the right WOG-rated valve for your needs.

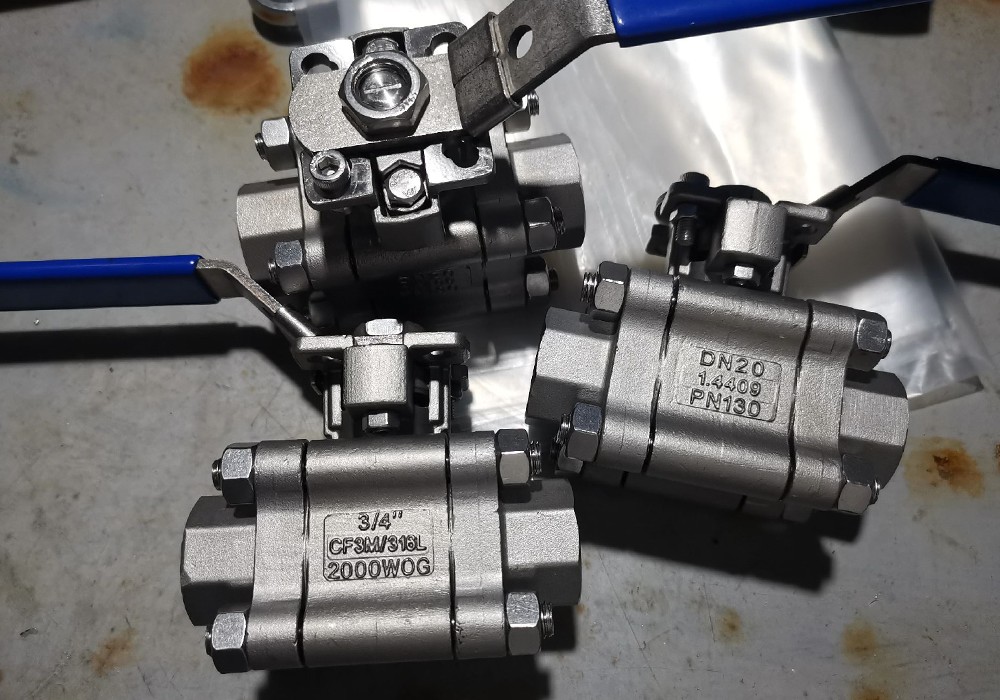

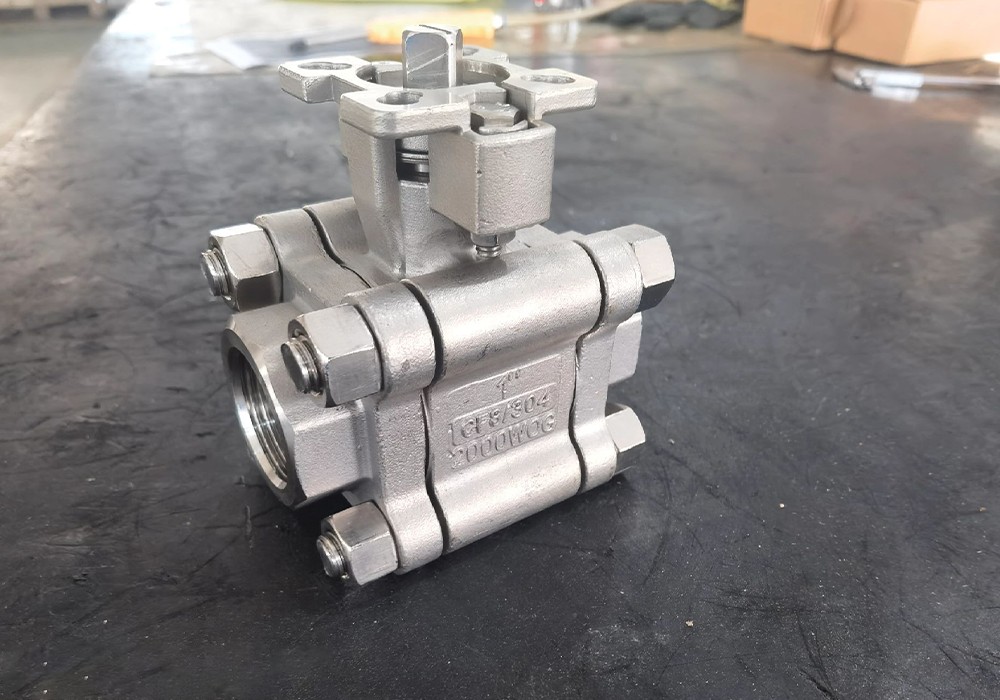

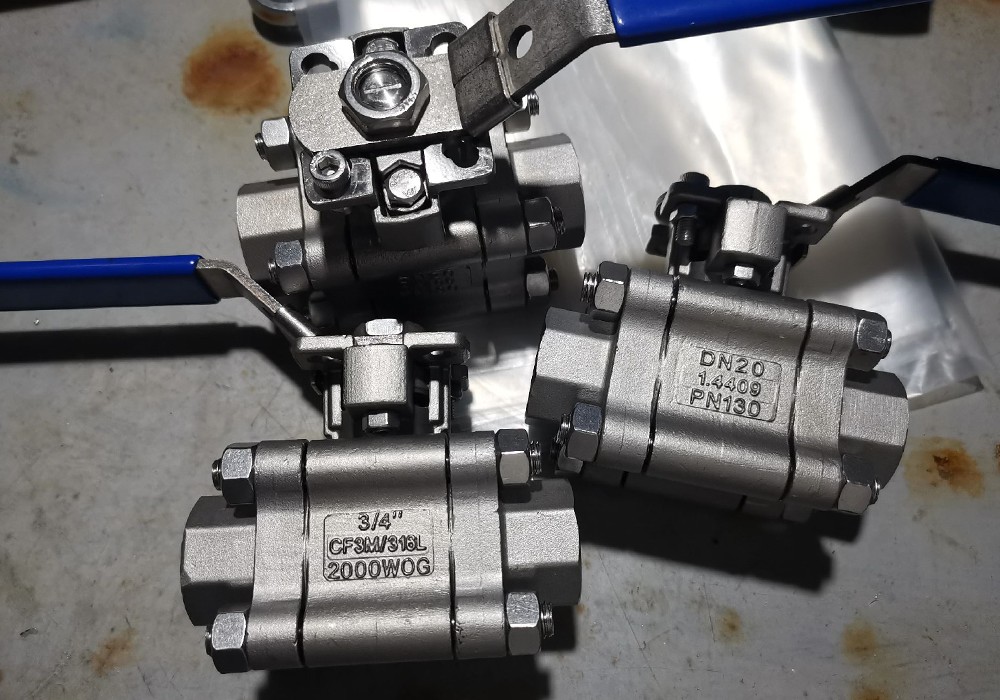

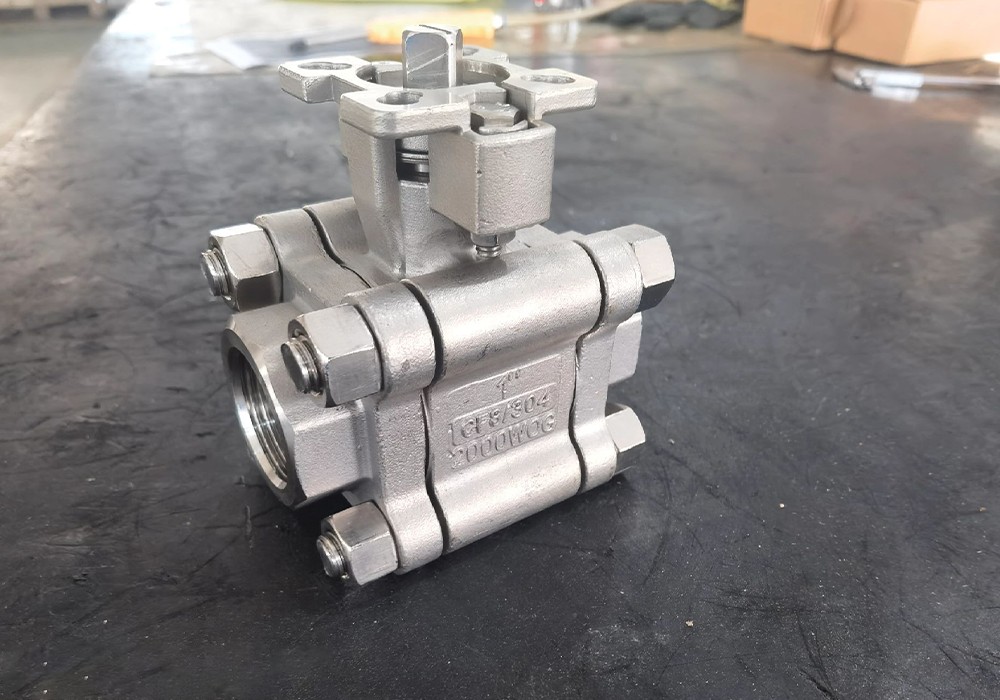

️ How to Read Valve Markings

Most valves are marked with abbreviations like:

• 600 WOG

• 1000 CWP

• 150 SWP

• ANSI Class 150

A manufacturer builds a 600 WOG valve to manage 600 PSI at room temperature with water, oil, or gas, excluding steam.

- Before you make a choice, think about the material.

- This could be brass or stainless steel.

- Also, consider the type of connection.

- Options include NPT or flanged.

- Finally, think about how you will use it.

Summary: What Is a WOG Valve?

A WOG valve is simply a valve rated to withstand a specific pressure with water, oil, or gas at room temperature.

A safety standard, not a product type, tells you whether a valve will hold up in your specific application.

Understanding this rating helps engineers, contractors, and procurement managers choose the right valve and avoid costly or dangerous failures.

Why Choose Our WOG Valves?

As a valve manufacturer, we provide a complete range of WOG-rated valves. These valves meet international standards for performance and safety.

✅ Strict material selection (brass, stainless steel 304/316)

✅ Tested under real working conditions (pressure + temperature)

✅ Certifications available upon request (ISO, CE, etc.)

✅ Customization for special applications

We can provide the right valve for your needs. This applies whether you are using water in city systems, oil in factories, or gas for heating and cooling.

Need Help Choosing the Right WOG Valve?

At COVNA, we’re more than just a manufacturer — we’re your valve partner. Contact us today for expert advice, technical sheets, or to order high-quality, certified WOG-rated valves.

Contact us now