What Is a Globe Valve? — Comprehensive Guide for Buyers

Introduction: Understanding Globe Valves

A globe valve is a type of valve widely used in industrial and commercial piping systems to regulate or shut off fluid flow. Its name comes from its spherical-shaped body. Inside, it houses a movable disk or plug. This disk controls flow by moving perpendicular to the seat.

Unlike gate valves that offer simple on/off control, it provides precise throttling and flow control. This makes it ideal for applications where flow rate adjustment is critical.

Globe Valve Structure and Working Principle

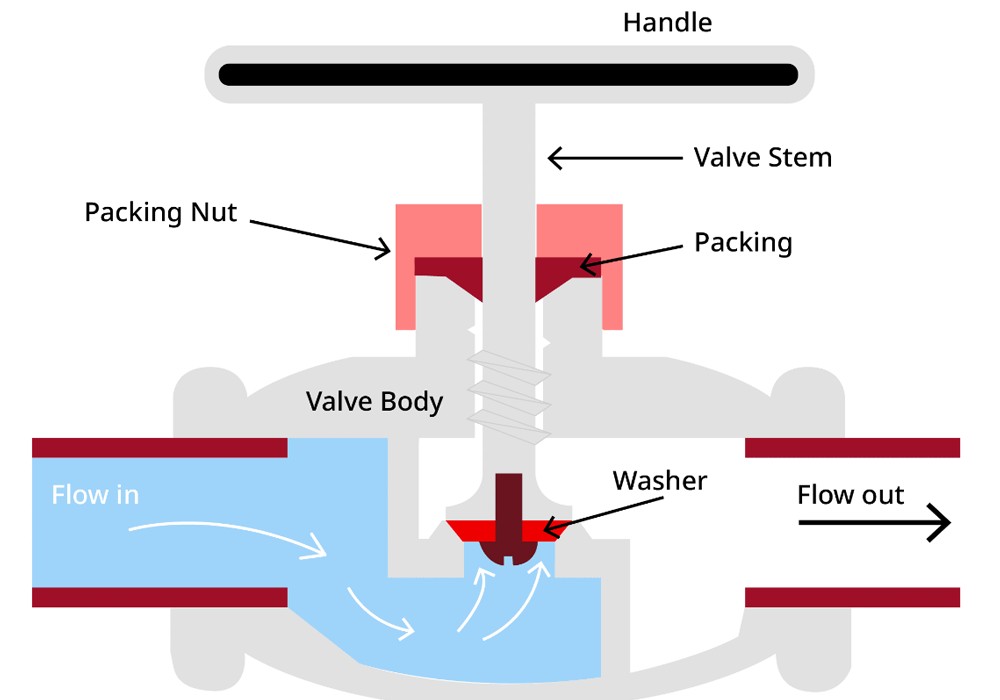

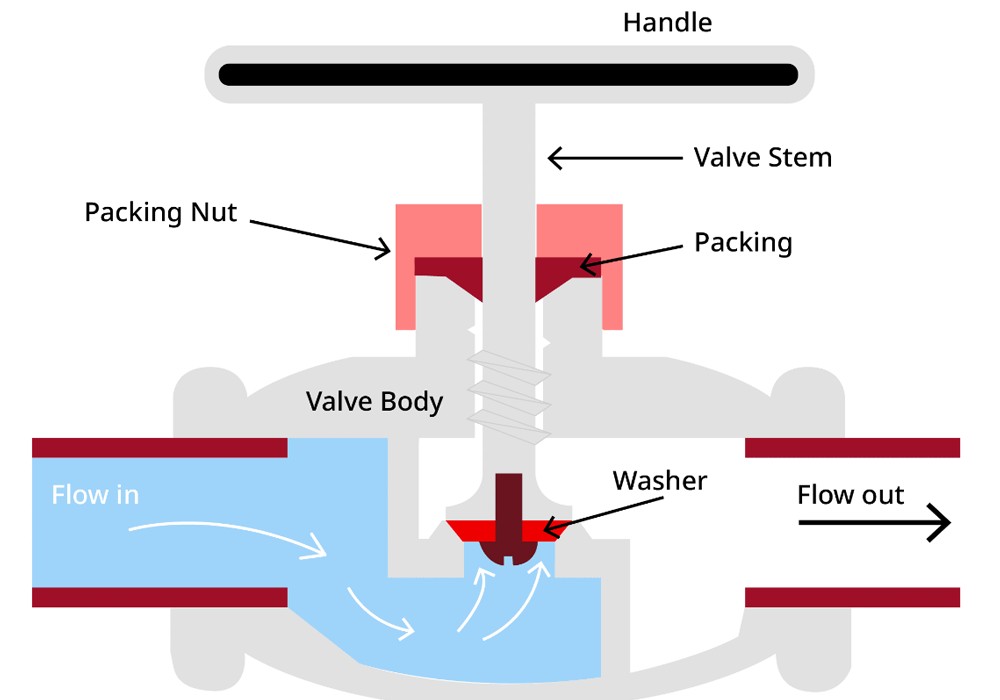

It typically consists of these main parts:

• Body: The outer casing shaped like a globe or spherical shell.

• Bonnet: The cover attached to the body, enclosing the internal components.

• Stem: The rod connected to the handwheel or actuator, which moves the disk.

• Disk (or Plug): The movable part that closes against the seat to stop flow or opens to allow fluid passage.

• Seat: The stationary ring that the disk seals against to stop flow.

Working Principle:

When the handwheel is turned, the stem moves the disk up or down. Moving the disk away from the seat opens the valve, allowing fluid to pass through the body.

Lowering the disk onto the seat closes the valve, stopping flow. Because the fluid does not flow straight through the globe valve, it changes direction inside the body. This causes a higher pressure loss compared to other valves.

Why Choose a Globe Valve?

Key Advantages

• Excellent Flow Control: Globe valves allow precise throttling of flow, thanks to their design.

• Tight Sealing: The disk and seat provide reliable shutoff to prevent leakage.

• Durability: They withstand high pressure and temperature, suitable for harsh conditions.

• Versatility: Applicable for liquids, gases, and steam across industries like power plants, chemical processing, water treatment, and HVAC.

Considerations

• Higher Pressure Drop: The flow path through the valve body creates resistance, causing pressure loss.

• Not Ideal for Fully Open or Closed Applications: Better for regulation than for simple on/off uses.

• Maintenance: The moving parts and seat require periodic inspection and replacement depending on the working medium.

Globe Valve vs Other Valves

When selecting valves, understanding differences helps make the right choice:

| Feature | Globe Valve | Gate Valve | Ball Valve |

| Flow Control | Excellent (precise throttling) | Poor (mainly on/off) | Moderate |

| Pressure Drop | Higher due to flow direction | Low, straight flow path | Low |

| Sealing | Tight, but more wear on seat | Good but may leak under wear | Excellent |

| Applications | Flow regulation and shut-off | Full open or full close | Quick operation and shut-off |

For applications requiring accurate flow regulation, globe valves are usually preferred.

Applications of Globe Valves

Globe valves are common in various industries, including:

• Water treatment plants

• Oil and gas processing

• Power generation

• Chemical and petrochemical plants

• HVAC systems (Heating, Ventilation, Air Conditioning)

• Pharmaceutical manufacturing

Their ability to regulate flow with high accuracy makes them indispensable in critical processes.

Additional Benefits of Globe Valves in Industrial Systems

In addition to precise flow control, globe valves excel in offering easy maintenance and repairability. Because of their straightforward design, maintenance teams can replace worn-out parts such as seats and discs. You can do this without removing the entire valve from the pipeline. This feature reduces downtime and maintenance costs significantly, which is essential in high-demand industrial environments.

Moreover, you can equip globe valves with various actuation methods, including manual handwheels, pneumatic, electric, or hydraulic actuators. This flexibility allows integration into automated control systems, enabling remote operation and improving safety by reducing manual intervention in hazardous areas.

Material Selection and Customization for Globe Valves

Selecting the right material for globe valves is crucial to ensure performance and longevity. Manufacturers make globe valves from different materials. These materials include stainless steel, carbon steel, brass, and special alloys. The choice depends on the fluid type, temperature, and pressure.

These materials provide resistance to corrosion and erosion. These materials are resistant to corrosion and erosion.

Additionally, you can customize sealing materials such as PTFE or metal seats. This ensures compatibility with aggressive chemicals or high-temperature steam.

At COVNA, we provide tailored globe valve solutions designed to meet your specific process requirements. If you need valves that resist corrosion or are good for sanitary use, our engineering team will help you. We will recommend the best materials and design features for your needs.

How to Choose the Right Globe Valve

When selecting a globe valve, consider:

• Material Compatibility: Body and internal parts should resist corrosion and wear based on the fluid type. Common materials include stainless steel, brass, and cast iron.

• Pressure and Temperature Ratings: Ensure the valve can handle the system’s maximum operating conditions.

• Connection Type: Flanged, threaded, or welded connections based on pipeline design.

• Size and Flow Capacity: Match valve size to system requirements to avoid pressure drop or noise.

• Actuation Method: Manual handwheel, pneumatic, or electric actuators depending on automation needs.

Why Buy Globe Valves from COVNA?

As a leading globe valve manufacturer, we offer:

• High-Quality Materials: Our valves use premium stainless steel, brass, and specialized alloys for longevity.

• Strict Quality Control: We test each valve to meet international standards (API, ISO, CE), ensuring performance and reliability.

• Customization: Tailored valve sizes, pressure ratings, and actuation options to fit your exact needs.

• Expert Support: Our technical team helps you select the right valve and provides after-sales service.

• Competitive Pricing & Fast Delivery: Ensuring you get value and quick project turnaround.

Contact us today to get a quote or learn more about our globe valve product range!

Modern Technology and Manufacturer Importance

In modern industrial settings, globe valves are increasingly integrated with smart technologies. Manufacturers install sensors on these smart globe valves to monitor valve position, temperature, and pressure in real time. Such integration enables predictive maintenance and remote control, improving overall operational efficiency and reducing the risk of unexpected downtime.

Choosing the right globe valve manufacturer is just as important as selecting the valve itself. A reliable manufacturer provides not only high-quality products but also comprehensive technical support, customization options, and after-sales service. Partnering with an experienced globe valve supplier ensures smooth progress at every stage of your project—from design and installation to long-term performance.

Conclusion

A globe valve is an essential component in many industrial systems for controlling fluid flow precisely and reliably. Understanding its design, working principle, advantages, and selection criteria will help you make informed purchasing decisions.

For reliable, high-performance globe valves built to fit your needs, choose COVNA—your trusted expert in valve solutions.

FAQ

Q1: Can globe valves be used for gas and steam?

Yes, globe valves are suitable for gases, steam, and liquids, provided materials and seals match the application.

Q2: How often should a globe valve be maintained?

Inspect seals and stems regularly to prevent leaks and keep your system running smoothly, as maintenance intervals can vary.

Q3: What is the typical lifespan of a globe valve?

With proper maintenance and correct application, globe valves can last many years, often over 10 years.