What Does a Check Valve Do?

In fluid control systems—whether in water supply, industrial pipelines, or chemical processing—a check valve plays a small but critical role. If you're asking “what does a check valve do?”, you're likely in the right place to discover how this simple device helps protect your system, improves efficiency, and saves costly maintenance.

This article explores in depth what a check valve does, how it works, and why it’s essential for anyone operating pumps, piping, or pressurized fluid systems. Whether you're an engineer, plant manager, or procurement specialist, this guide will help you make informed decisions—especially when choosing a high-quality check valve from a trusted manufacturer.

✅ What Does a Check Valve Do?

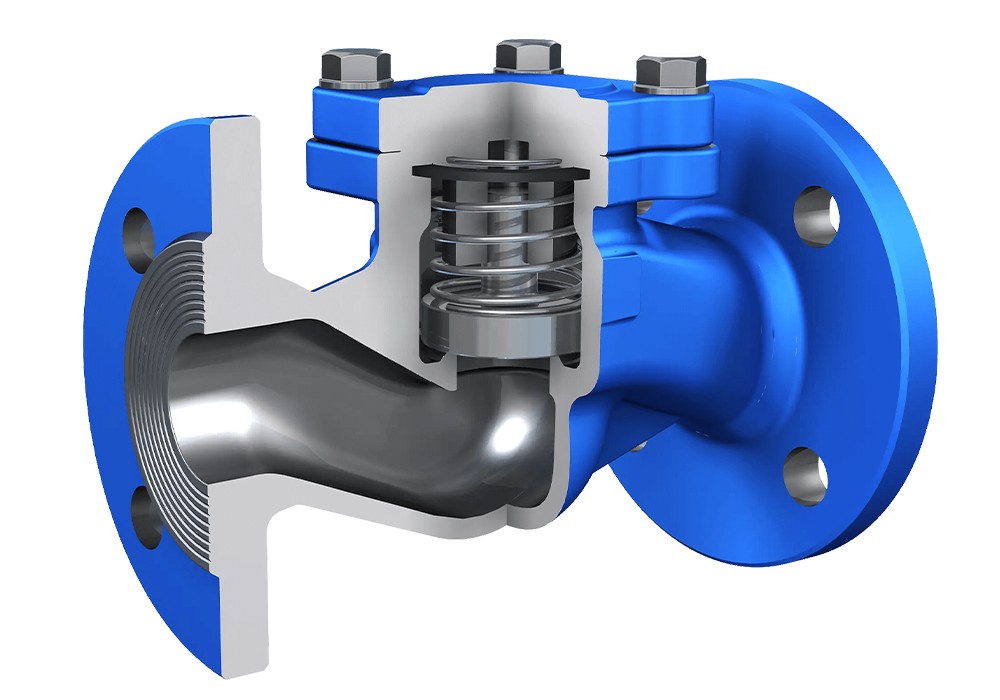

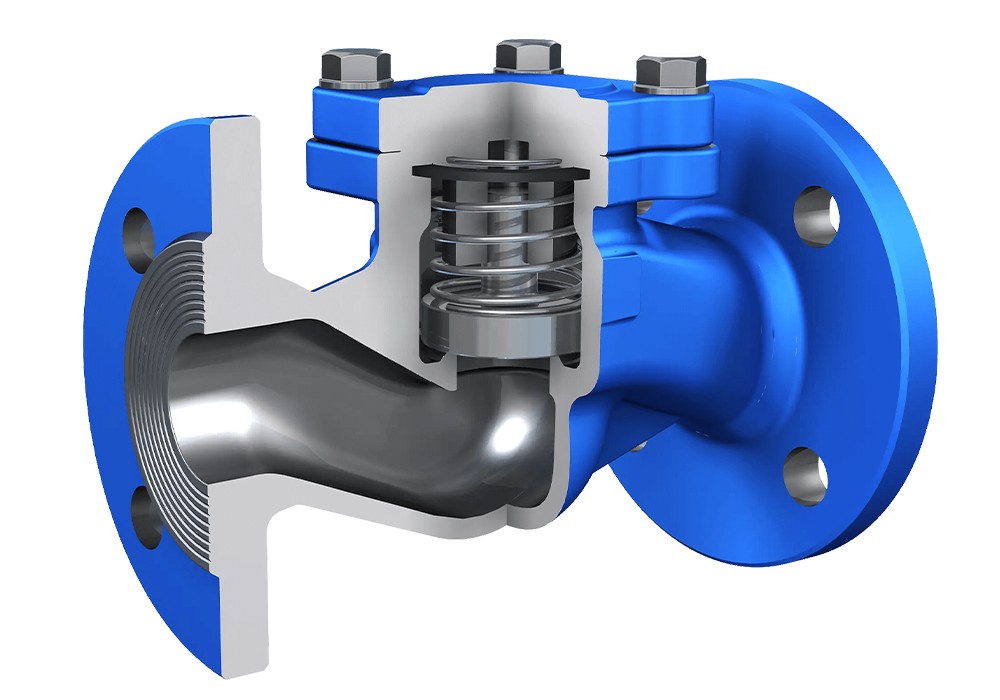

A check valve is a type of valve that allows fluid (liquid or gas) to flow in one direction only, automatically preventing reverse flow. It opens when the pressure of the fluid in the forward direction is greater than the pressure on the opposite side. When flow reverses or stops, the valve shuts to protect pumps, compressors, tanks, and the overall pipeline system.

It’s essentially the “gatekeeper” in your piping system—quietly ensuring everything flows the right way.

How Does a Check Valve Work?

• Flow begins ➜ fluid pushes the valve open.

• Flow continues ➜ valve stays open as long as forward pressure remains.

• Flow stops or reverses ➜ gravity, a spring, or backpressure causes the valve to close immediately.

This non-return action is fully automatic—no actuator or external control is required.

Depending on the design, the closure mechanism may be a disc, ball, piston, flap, or diaphragm.

⚙️ Types of Check Valves

Each type of check valve suits a different application and performance demand. Here's a quick overview:

| Type | Mechanism | Best For |

| Swing Check Valve | Hinged disc swings open and shut | Low-velocity systems (water, sewage) |

| Ball Check Valve | Ball rises/falls with flow | Viscous fluids, slurries |

| Spring Check Valve | Spring-loaded disc closes quickly | Fast shut-off, vertical installations |

| Lift Check Valve | Disc lifts vertically | High-pressure, horizontal lines |

| Diaphragm Check Valve | Flexible diaphragm opens/closes | Low-pressure systems, silent operation |

At our company, we manufacture a full range of these types, tailored for different flow rates, pressures, and industrial uses.

Key Functions of a Check Valve

• Prevents Backflow

This is the core function. Backflow can damage pumps, reverse chemical reactions, and contaminate clean water supplies.

• Protects Equipment

Reverse pressure can damage compressors, filters, and meters. A check valve ensures pressure flows in a single direction, acting as a silent protector.

• Eliminates Water Hammer

In high-speed systems, sudden stopping of flow causes pressure spikes—known as water hammer. Spring-loaded or damped check valves reduce this effect.

• Maintains System Pressure

In pressurized systems, it holds pressure in place when the pump is off—preventing pressure drop or fluid loss.

• Reduces Downtime

By stopping reverse flow and pressure shocks, check valves help minimize system failures and downtime.

️ The Role of Check Valves in Pressure Surge Protection (Water Hammer)

While most people associate check valves solely with backflow prevention, a lesser-known yet critical function is their ability to mitigate pressure surges, commonly known as water hammer. This phenomenon occurs when a fluid in motion is forced to stop or change direction suddenly—typically when a pump shuts off or a valve closes quickly.

A poorly selected or sluggish check valve can worsen the surge, leading to:

• Loud banging sounds in the pipeline

• Pipe fatigue and joint failure

• Damage to pumps, seals, and gauges

To combat this, non-slam or spring-assisted check valves are often used. These are engineered to close quickly and silently, reducing the momentum of the reversing flow and preventing shock waves from forming.

So, beyond backflow control, check valves—when properly chosen—can prolong the lifespan of your entire piping system by softening hydraulic transitions and stabilizing pressure.

Where Are Check Valves Used?

Check valves are found in almost every industry:

• Water and wastewater treatment

• Heating, ventilation, air conditioning (HVAC)

• ⚡ Power generation and steam systems

• ️ Oil and gas pipelines

• Chemical and pharmaceutical processing

• Firefighting and sprinkler systems

• Food and beverage manufacturing

If your system involves flow control, there's likely a check valve involved—and possibly several.

️ How to Choose the Right Check Valve for Your System

Choosing the right check valve depends on a few key factors:

• Medium Type: Is the fluid clean water, slurry, oil, gas, or a corrosive chemical? Material compatibility is crucial—stainless steel or PVC may be ideal for corrosive environments, while brass or cast iron suits water and air systems.

• Installation Orientation: Some check valves (like swing check valves) work best in horizontal pipelines, while others (like spring check valves) perform well in vertical installations.

• Flow Rate & Pressure: Knowing your system’s operating pressure and flow characteristics helps avoid under-sizing or oversizing the valve, both of which can reduce performance and cause wear.

• Space Constraints: Some industrial setups require compact valve bodies or silent operation—especially in HVAC or process lines where space and noise matter.

If you're unsure, our team offers free consultations to help you determine the best valve type for your system conditions.

⚠️ Why Check Valve Quality Matters

Not all check valves are equal. Poorly made valves may:

• Leak or fail to close fully

• Slam shut, causing noise and water hammer

• Wear out quickly, especially in corrosive or abrasive fluids

That's why selecting a trusted check valve manufacturer matters. You need durable materials, precision manufacturing, and correct sizing.

At our company, we offer:

• ✅ High-performance check valves in stainless steel, brass, cast iron, and PVC

• ✅ ISO/CE-certified production with tight quality control

• ✅ Customization based on flow rate, medium type, and pressure class

• ✅ Global shipping and technical support

Why Work With a Trusted Check Valve Manufacturer?

As a manufacturer with 25 years of experience in the valve industry, we understand the demands of industrial, municipal, and commercial applications. What sets us apart?

• Engineered Precision – Each valve is tested under pressure before delivery.

• OEM/ODM Services – Need custom sizes, materials, or branding? We support full customization.

• Global Logistics – Fast delivery and support worldwide.

• Technical Support – Our engineers provide installation guidance, product selection, and after-sales service.

When it comes to fluid control, reliability is everything. Don’t risk system failure with low-grade valves. Choose a trusted partner who understands both engineering and application.

Let's Build a Reliable Flow System Together

Your piping system is only as strong as its weakest component—and the check valve is often the silent guardian that determines long-term reliability. Whether you're upgrading aging infrastructure, building a new processing line, or designing a high-performance fluid system from scratch, partnering with an experienced valve manufacturer ensures peace of mind.

We’ve helped clients in industries from municipal water treatment to battery production and chemical engineering solve backflow problems, improve efficiency, and reduce costly downtime. Let us help you do the same.

Have a project in mind? Reach out to our technical sales team for expert guidance or request a quote within 24 hours. Together, we’ll find the check valve that fits your system—and your standards.