Video

| |

| COVNA Electric Butterfly Valve Introduction | Employees explain COVNA explosion-proof electric valve |

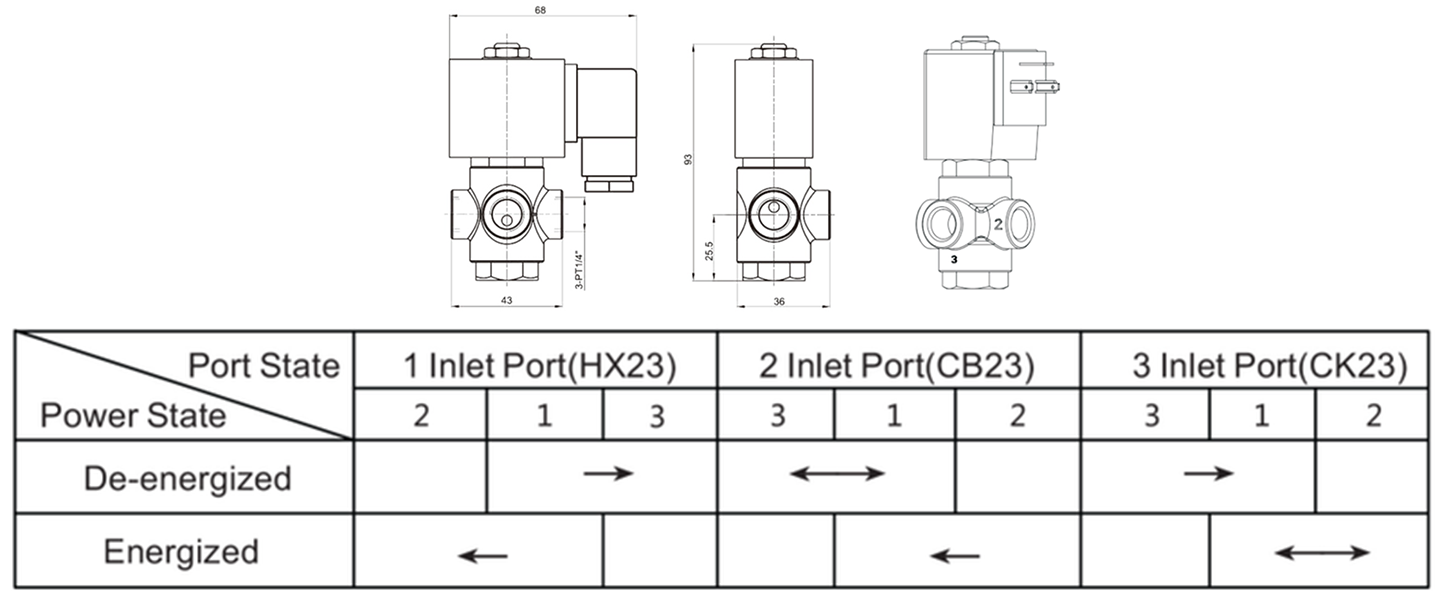

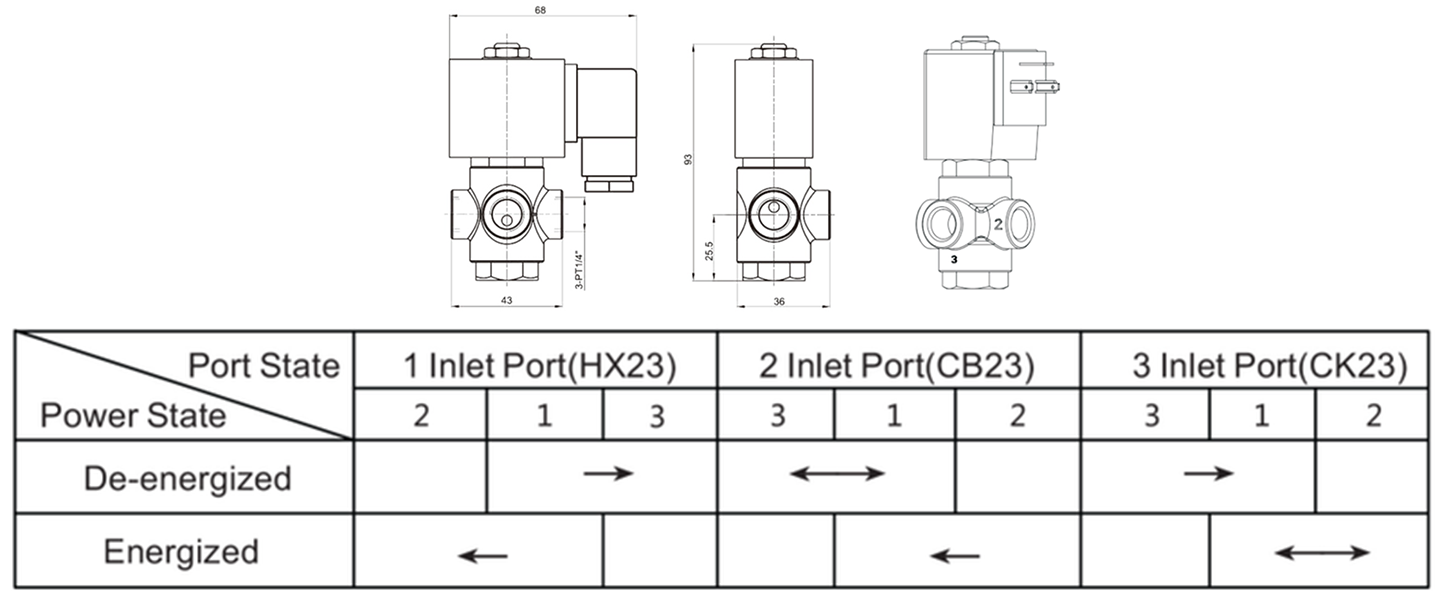

Parameters

Why choose COVNA

1. Pipeline valves comply with API 6D standards, and quality management complies with ISO 9001 standards.

2. Free samples can be provided for your testing

3. Valves can be manufactured according to your drawings and laser-engraved with your company's logo

4. We also have a complete control valve and ball valve assembly workshop, covering an area of 6,800 square meters, with a daily output of 5,000 control valves and ball valves

5. At the same time, we have a complete control valve and ball valve assembly workshop, covering an area of 6,800 square meters, with a daily output of 5,000 control valves and ball valves