How Control Valve Works-Complete Guide

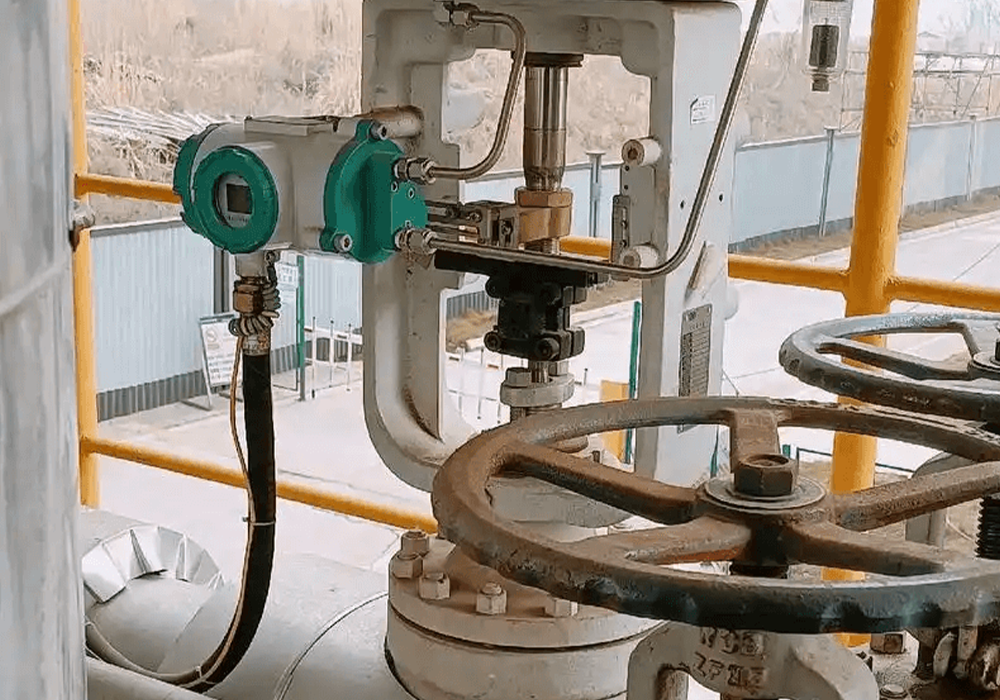

Control valves help automated systems work smoothly. You can find them in places like oil refineries, power stations, drug factories, food plants, and water treatment systems. But how do control valves work, and why are they so critical?

This guide will help you understand what control valves do, how they work, the different types, and how to pick the right one. No matter if you’re an engineer, work in a factory, or help with buying machines, you’ll find useful information here. And if you're looking to buy control valves, we’ll also explain why picking a good manufacturer is so important.

What Is a Control Valve?

A control valve is a device that helps control how much fluid—like gas, liquid, steam, or slurry—flows through a pipe. It opens or closes based on signals it gets from a controller. These signals usually come from sensors that measure things like pressure, temperature, flow, or level.

Put simply, a control valve changes the flow to keep everything running at the right level or setting.

The Working Principle: How Control Valve Works

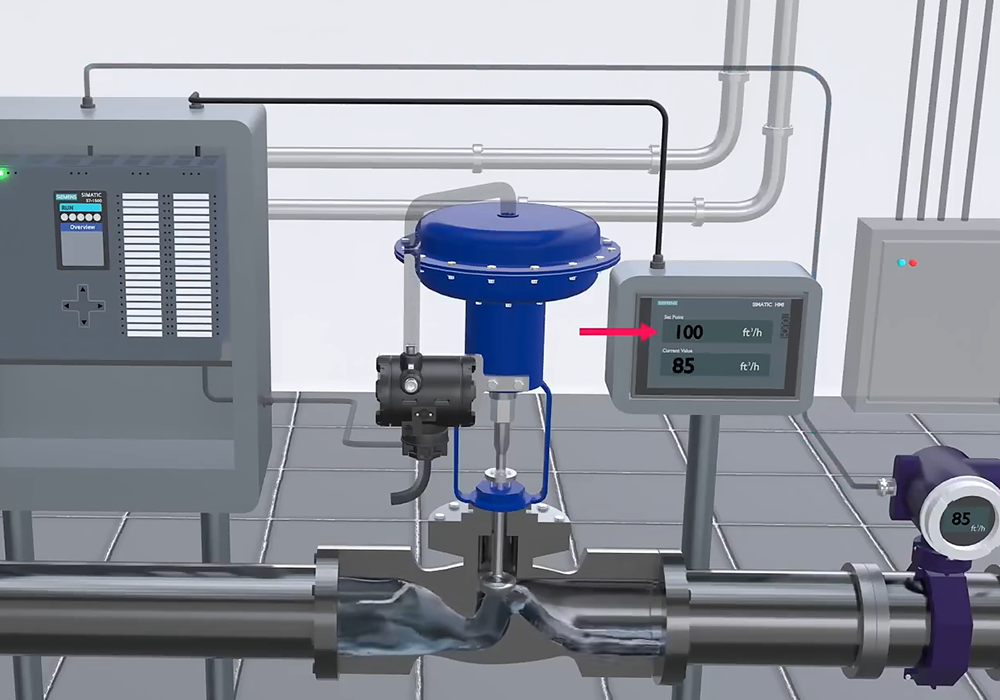

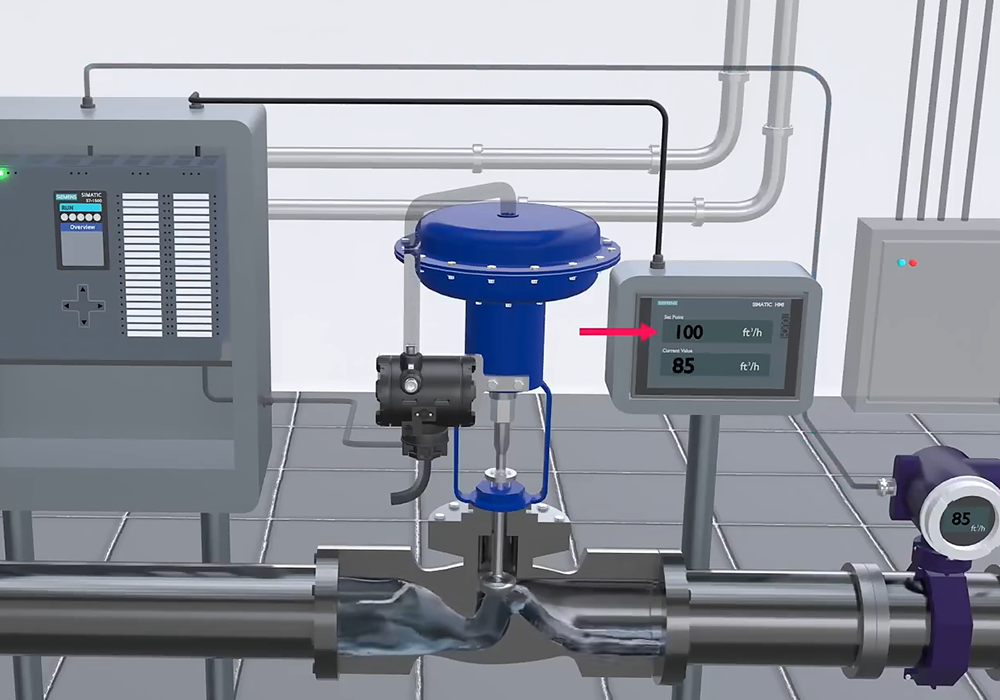

At its core, a control valve receives an electronic or pneumatic signal from a controller. This signal tells the valve how much to open or close to maintain the desired process condition.

Step-by-Step: What Happens Inside a Control Valve?

• Signal Input: The valve receives a signal (usually 4–20 mA for electrical or 3–15 psi for pneumatic).

• Actuator Movement: The actuator—either electric, pneumatic, or hydraulic—converts this signal into linear or rotary motion.

• Valve Positioning: The actuator moves the valve stem or shaft, adjusting the position of the valve plug, disc, or ball.

• Flow Regulation: The fluid flow changes accordingly, increasing or decreasing based on the valve opening.

• Feedback Loop: A positioner ensures that the valve reaches the correct position and maintains it in real time.

Example: Controlling Steam Flow

Imagine a boiler system where steam pressure must stay at 8 bar. If pressure drops below this, the controller sends a signal to the control valve to open more and let in more steam. If it rises above 8 bar, the valve closes slightly to restrict flow.

This continuous modulation ensures stability, safety, and efficiency.

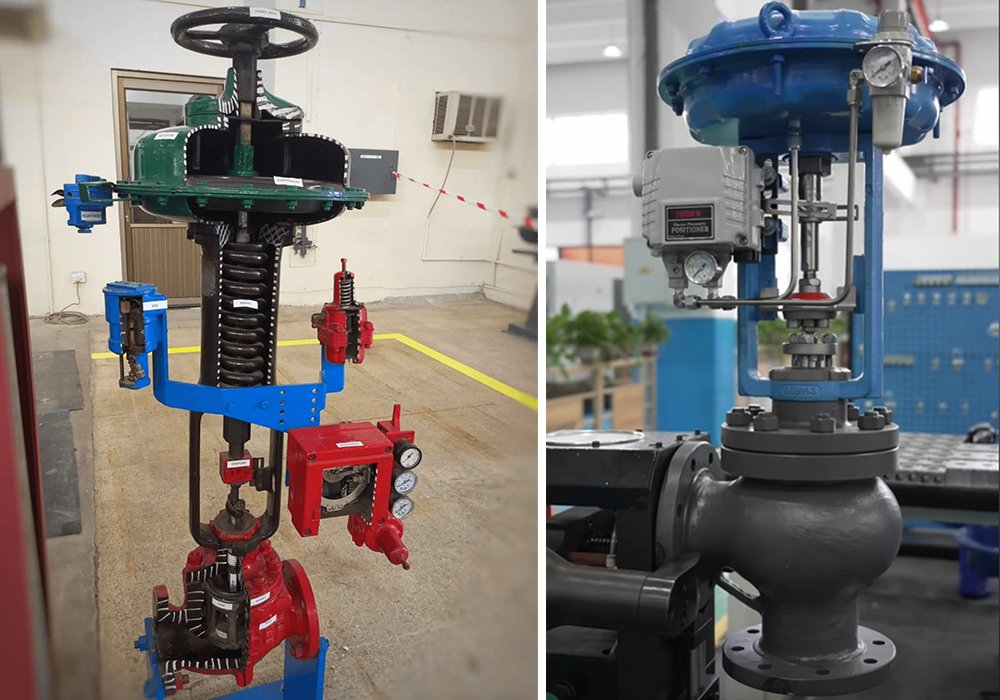

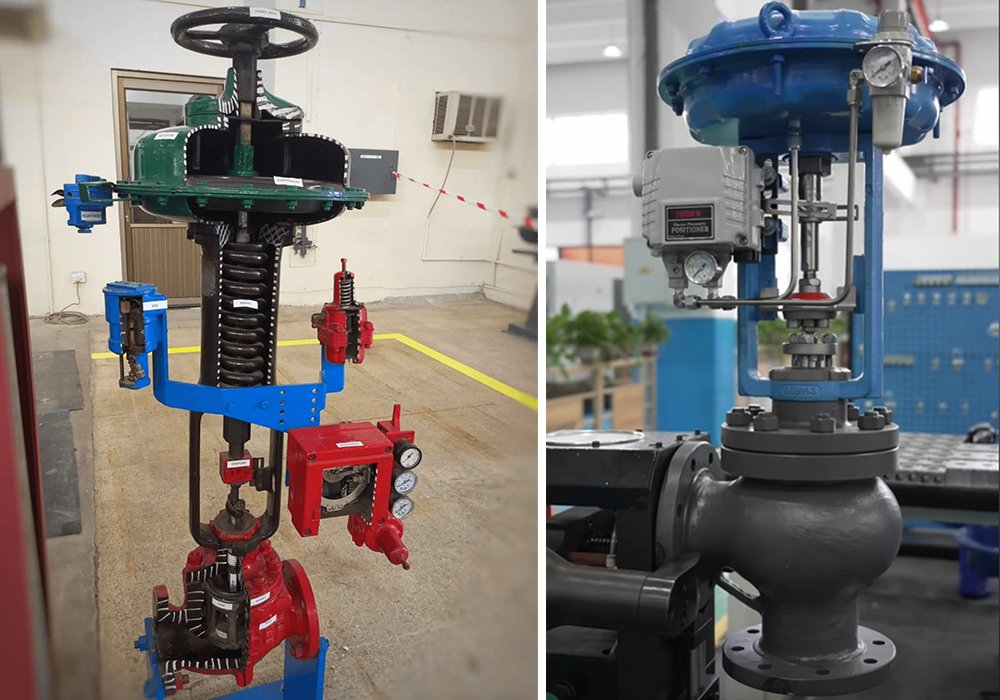

Key Components of a Control Valve

To understand how control valves work in detail, it's important to know their internal structure. The main components include:

• Body: The valve housing that holds all internal parts.

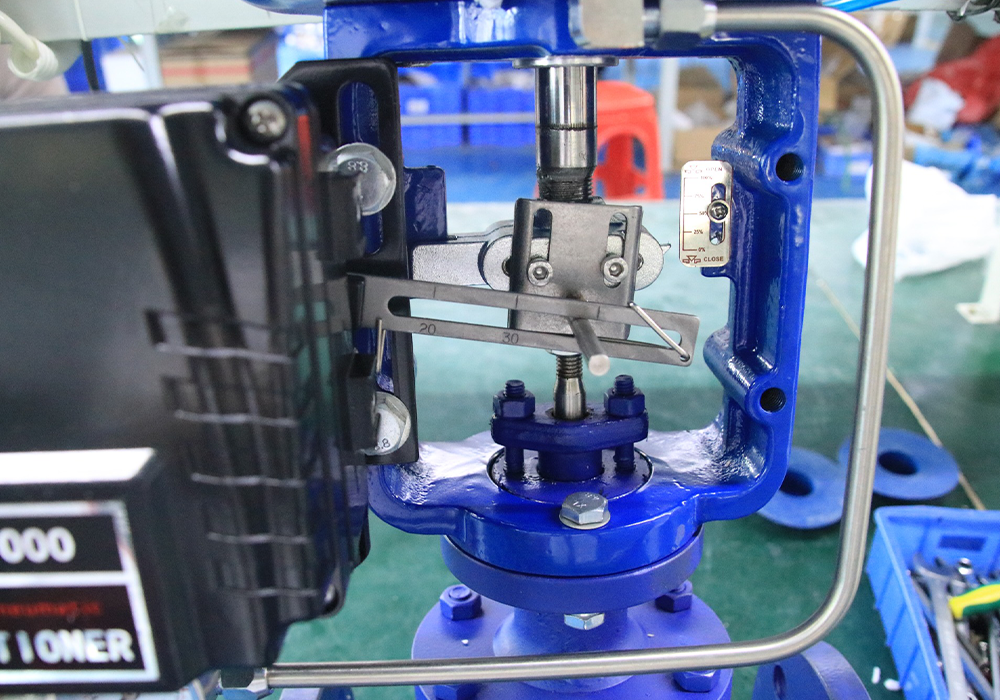

• Trim: Internal parts like plug, seat, and stem that control fluid flow.

• Actuator: Provides the force to move the valve (pneumatic, electric, hydraulic).

• Positioner: Ensures accurate valve positioning based on the control signal.

• Bonnet: Covers the valve stem and allows packing to prevent leaks.

• Packing: Prevents process fluid from leaking around the stem.

• Plug or Disc: The movable element that regulates flow.

• Seat: Fixed surface against which the plug seals.

Types of Control Valves

Control valves are categorized based on their motion and internal mechanism:

1. Linear Motion Control Valves

• Globe Valves: Precise throttling, common in steam and high-pressure systems.

• Diaphragm Valves: Good for corrosive or slurry media.

• Gate Valves (less common for modulation): Typically for on/off control.

2. Rotary Motion Control Valves

• Ball Valves: Quarter-turn, high flow capacity, suitable for fast shut-off and moderate throttling.

• Butterfly Valves: Cost-effective, compact, and suitable for large flows at low pressures.

• Plug Valves: Simple and reliable for basic modulation.

Each type has advantages depending on media type, pressure range, and control accuracy required.

Advanced Technologies in Modern Control Valves

Control valves are not just mechanical—they are part of the Industrial Internet of Things (IIoT) ecosystem.

Smart positioners allow for remote monitoring and diagnostics.

Valve health monitoring predicts failures before they occur.

Digital twins simulate performance and help in predictive maintenance.

As manufacturers, we offer integrated intelligent control valves that support protocols like HART, Modbus, and PROFIBUS, compatible with modern control systems.

✅ How to Select the Right Control Valve

Choosing the right valve involves both technical and practical considerations:

| Parameter | What to Consider |

| Fluid Type | Clean, viscous, corrosive, slurry |

| Pressure & Temperature | Max and normal operating conditions |

| Flow Rate | Required capacity and turn-down ratio |

| Valve Function | Throttling or on/off |

| Control Signal | Pneumatic or electric |

| Installation | Space, orientation, accessibility |

Need help sizing or selecting a valve? Our engineers offer free sizing and consultation services with guaranteed compatibility.

Actuation Methods: What Powers a Control Valve?

There are three main types of actuators:

1. Pneumatic Actuators

• Most commonly used due to their speed and reliability.

• Operate with compressed air (3–15 psi).

• Fail-safe modes (fail-open or fail-close).

2. Electric Actuators

• Ideal when compressed air isn't available.

• Offers precise positioning.

• Can be integrated with digital control systems.

3. Hydraulic Actuators

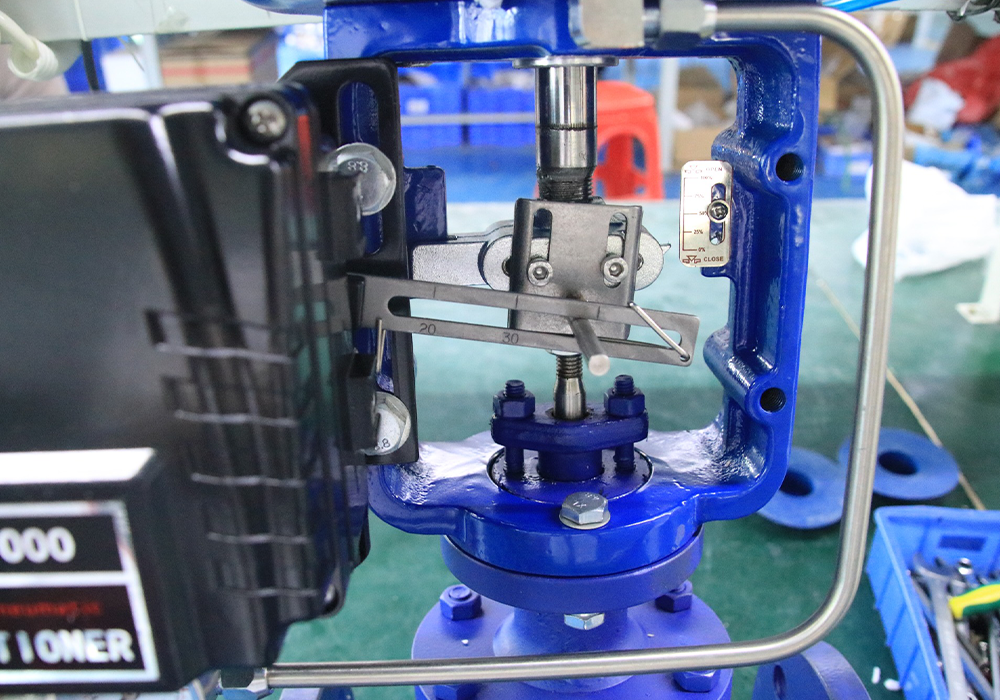

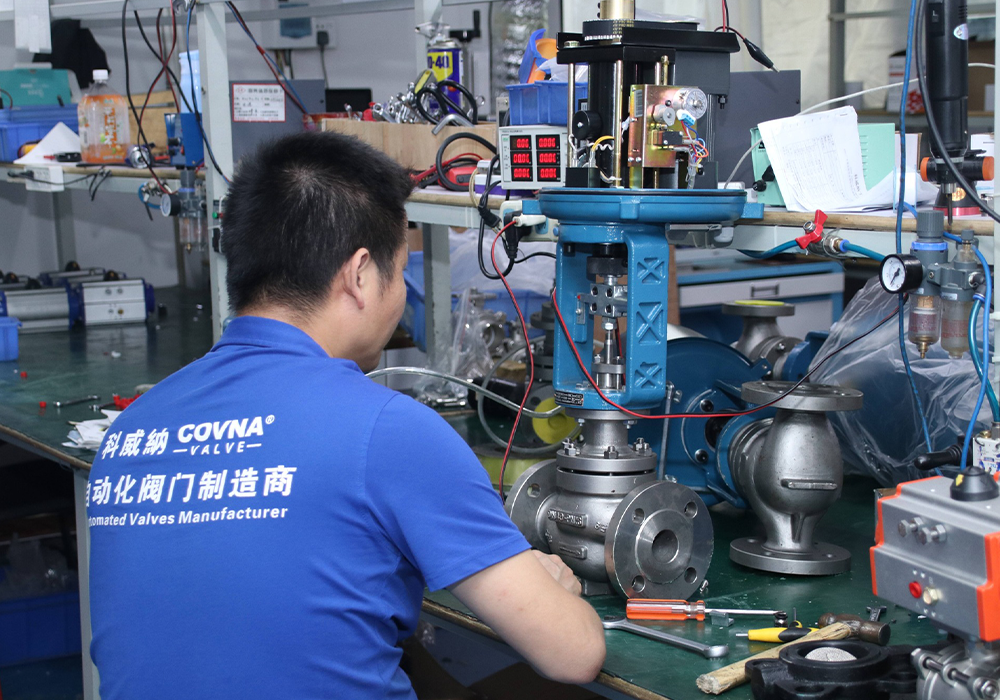

Control Valve Calibration and Maintenance

For optimal performance, control valves must be calibrated and maintained regularly:

• Calibration ensures the valve responds accurately to control signals.

• Maintenance includes replacing seals, cleaning internals, and verifying actuator function.

• Predictive maintenance using IoT sensors is increasingly common, reducing downtime and extending valve lifespan.

We provide valve health monitoring systems and preventive maintenance kits tailored to your plant conditions.

Sizing and Selection of Control Valves

Choosing the right control valve involves several critical factors:

• Flow characteristics (linear, equal percentage, quick open)

• Cv (Flow Coefficient)

• Pressure drop (ΔP)

• Operating pressure and temperature

• Media type (corrosive, slurry, clean fluid)

• Fail-safe requirements

Our engineers can assist you with valve sizing using advanced software and empirical data, ensuring the valve fits perfectly into your process loop.

Flow Characteristics and Valve Behavior

Control valves exhibit different flow characteristics, which define how the flow changes with valve position:

• Linear: Flow increases linearly with valve travel.

• Equal Percentage: Each increment of valve opening increases the flow by a fixed percentage (best for pressure control).

• Quick Opening: Most flow occurs at the beginning of valve travel (good for on/off applications).

We help you choose the correct flow characteristic based on your application to maximize stability, energy efficiency, and process response time.

Control Valve Calibration and Maintenance

To ensure optimal performance, regular calibration and maintenance of control valves is crucial. Over time, mechanical wear, process contaminants, and environmental factors can affect the accuracy and responsiveness of the valve.

Calibration involves adjusting the positioner or actuator to ensure that the valve opens and closes exactly as commanded. This typically requires:

• Verifying input signal response (e.g. 4-20 mA)

• Observing valve stem movement

• Using calibration tools or digital software

Maintenance tasks may include:

• Replacing worn packing or seals

• Cleaning valve trim and internals

• Checking actuator integrity and air supply

• Testing fail-safe function (fail-open or fail-close)

A well-maintained control valve can operate reliably for many years, reducing downtime and extending asset life. As a manufacturer, we offer preventive maintenance kits, remote diagnostics, and technical field services to support your operations.

️ Control Valves and Flow Dynamics: Avoiding Cavitation and Flashing

In high-pressure systems, two major issues must be avoided:

• Cavitation: Vapor bubbles form and collapse inside the valve, damaging trim and reducing efficiency.

• Flashing: Liquid turns to vapor and stays vapor—causing excessive noise and erosion.

We offer anti-cavitation trims, multi-stage pressure reduction, and special materials to combat these issues.

Environmental & Safety Considerations

As industries move toward cleaner and safer processes, control valves play an important role:

• Low-emission packing to comply with ISO 15848 and TA-Luft

• SIL-rated designs for safety instrumented systems

• Fail-safe actuation for critical applications

• Fire-safe designs for oil & gas

Our valves meet the latest environmental and safety regulations, including ATEX, CE, and API 607.

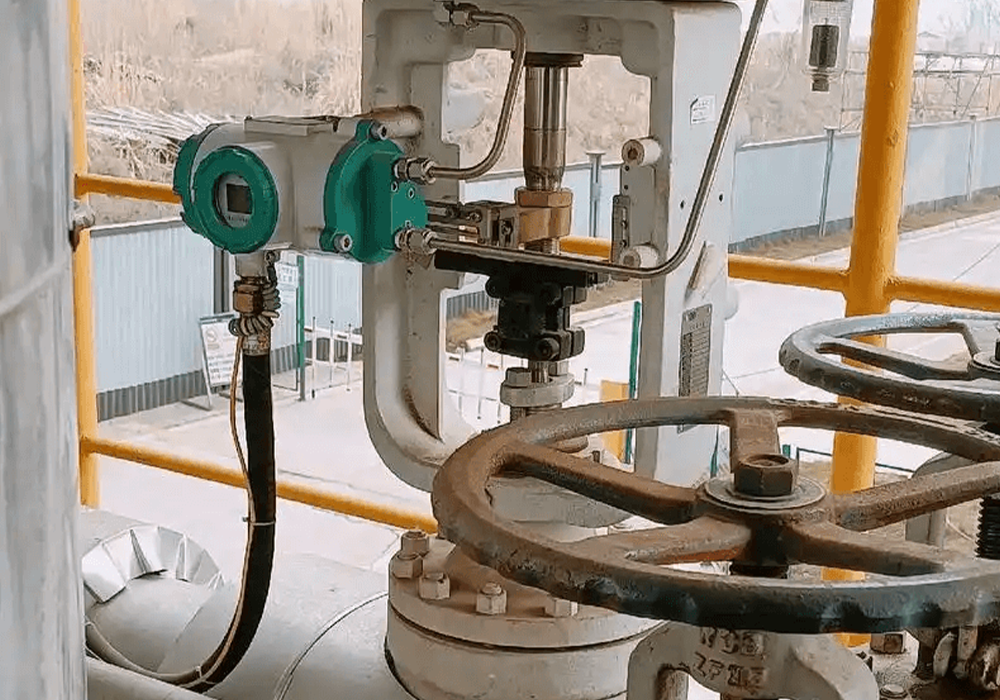

Applications Across Industries

Control valves are indispensable across a wide range of industries:

• Oil & Gas: Pressure reduction, flow control, separator outlet control.

• ⚡ Power Generation: Turbine bypass, boiler feedwater, steam modulation.

• Chemical & Pharma: Batch control, pH regulation, solvent mixing.

• Water Treatment: Flow control, chlorine dosing, filtration balancing.

• Food & Beverage: Ingredient dosing, CIP process, pasteurization temperature control.

As an experienced manufacturer, we tailor valves to each industry’s challenges—from corrosion resistance to sanitary design.

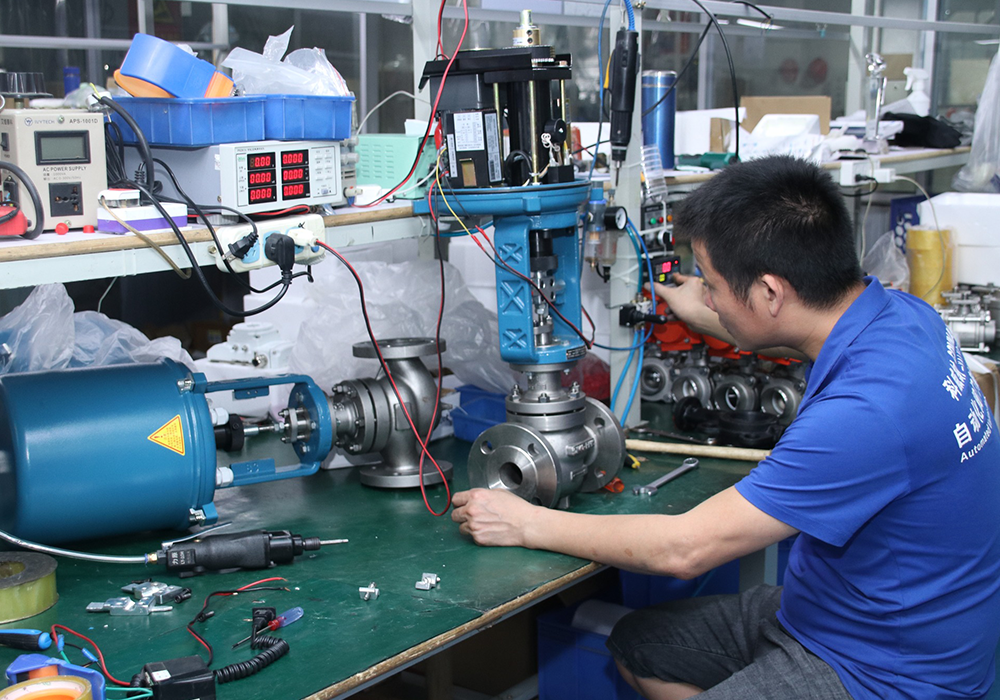

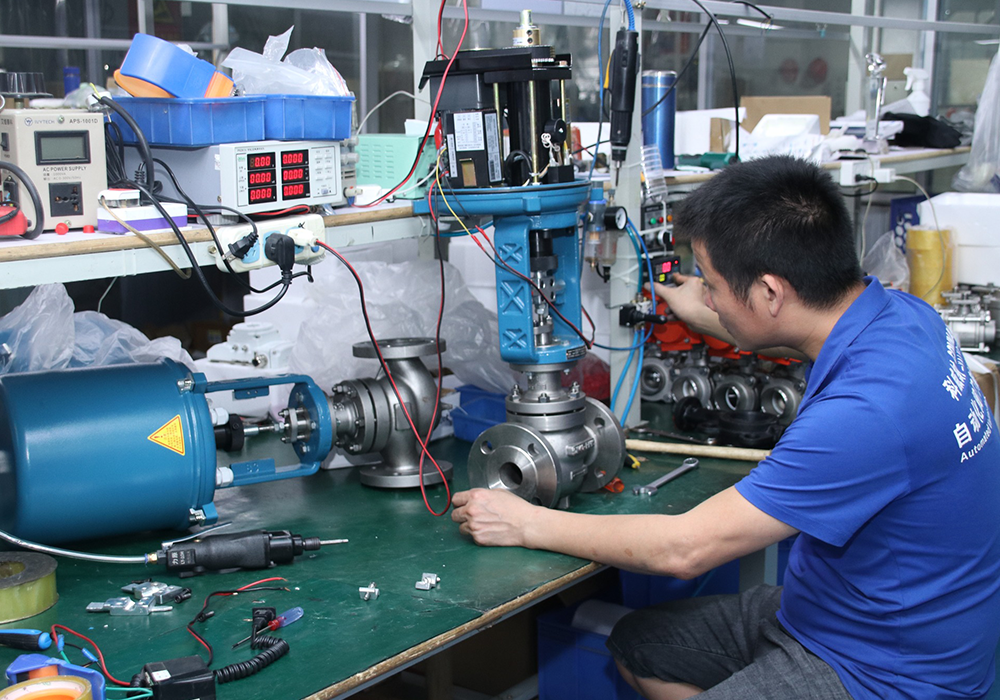

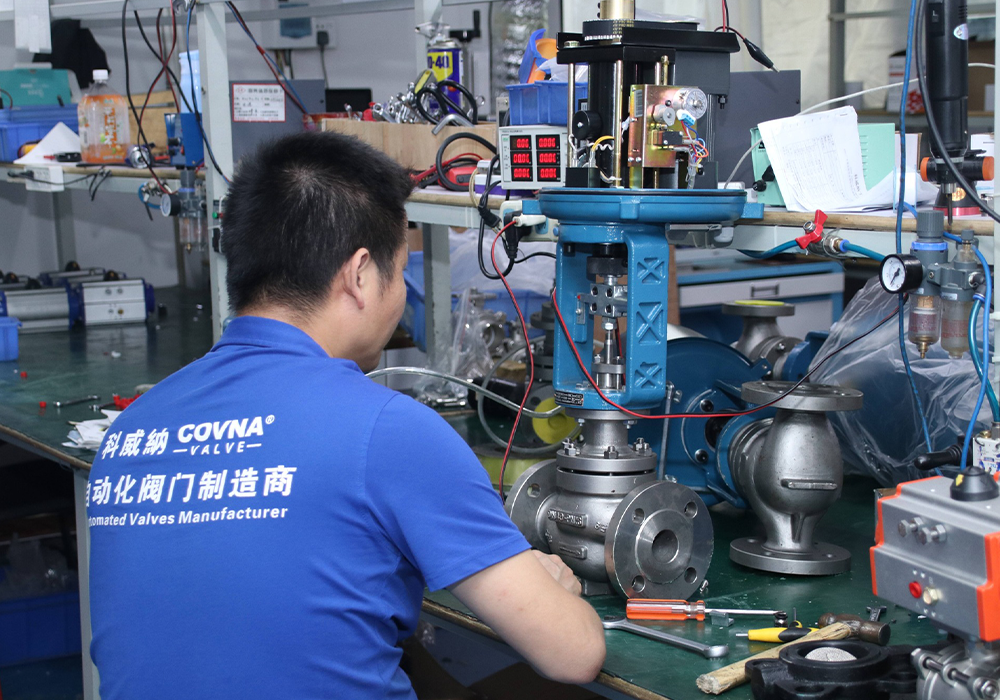

Why Choose Us As Your Control Valve Manufacturer?

With decades of manufacturing excellence and global supply experience, we offer:

• ✅ High-performance globe, ball, and butterfly control valves

• ✅ Customization based on flow rate, pressure class, or special materials

• ✅ Local service centers and rapid response field support

• ✅ Competitive lead times and pricing

• ✅ Strict quality control: ISO 9001, API 6D, CE-certified

Our valves are already in use by hundreds of process plants worldwide. Whether you need one valve or a fully integrated valve skid, our engineering team is ready to support your project from start to finish.

Contact Us Today

Want to improve your plant’s control accuracy and reliability? Need help selecting the right control valve for a specific process?

Talk to our valve experts today.

We’ll help you find the ideal solution for your application—and provide long-term support to ensure performance, safety, and cost-efficiency.

Quick Summary

| Topic | Insight |

| Control Valve | Regulates flow, pressure, or temperature |

| Key Components | Body, trim, actuator, positioner |

| Working Principle | Signal → Actuation → Plug movement → Flow control |

| Applications | Oil, gas, water, chemicals, food |

| Manufacturer Role | Design, customization, after-sales support |