In industrial automation systems, control valves may appear bulky and simple in design, often leading to them being overlooked. However, they play a crucial role in regulating process flow under complex working conditions. When a problem occurs, troubleshooting can be time-consuming and disruptive — impacting system startup, safety, control accuracy, and even environmental compliance.

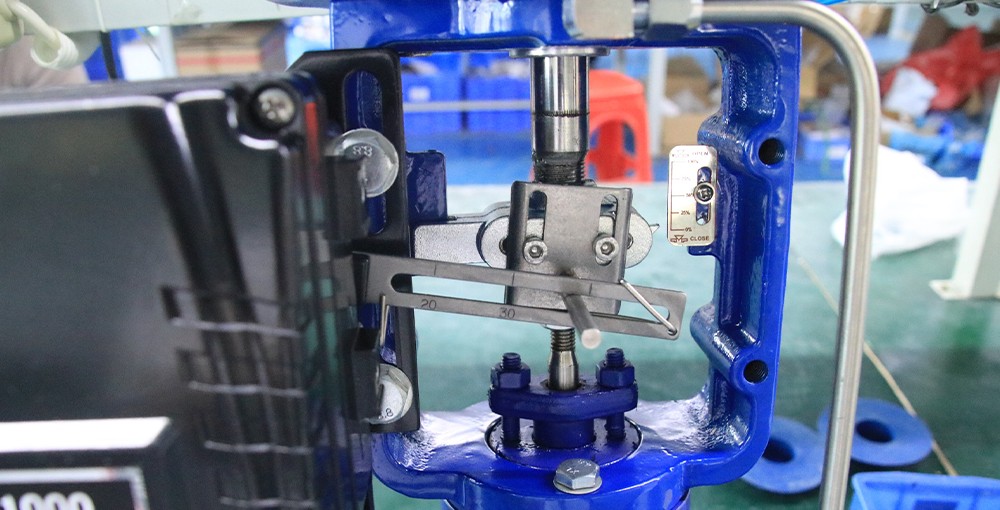

As a professional valve manufacturer, we understand that a key factor often underestimated is the valve’s working opening (valve opening percentage) — which directly influences the valve’s service life and performance.

Section 1: Why Small Valve Openings Shorten Valve Lifespan

Working at a small valve opening can significantly reduce the valve’s lifespan due to extreme flow conditions. Here’s why:

Severe Erosion and Cavitation:

At small openings, the throttling gap is minimal and flow velocity is at its highest. This leads to severe erosion and shortens the valve's lifespan.

Instability and Vibration:

Sudden changes in pressure and flow can exceed the mechanical rigidity of the valve, causing instability or vibration.

Control Failure:

In flow-to-close applications, small openings can lead to sudden jumps in operation, making precise control impossible.

Seal Damage:

Small openings position the valve plug dangerously close to the seat, increasing wear on sealing surfaces.

Incompatibility with Valve Type:

For instance, butterfly valves suffer from unbalanced torque at low openings, and dual-seat valves may vibrate due to uneven flow distribution.

✅ Best Practice:

For most valves, avoid operating below 10–15% opening. For high-pressure control valves, dual-seat valves, or flow-to-close configurations, maintain above 20–30% opening.

Section 2: Large Valve Openings = Longer Service Life

Field experience has proven that starting with the valve at a large opening (e.g., 90%) significantly extends service life — often by 1 to 5 times. Here’s how:

Erosion occurs gradually: Starting wide open, the wear concentrates on the tip of the plug. As erosion progresses, flow increases, so the valve gradually closes — using the full plug range over time.

Reduced turbulence: Larger gaps mean less velocity, fewer pressure drops, and reduced cavitation and erosion.

Real Case:

A chemical plant implemented this strategy and doubled the service life of their control valves.

️ Section 3: How to Increase Valve Opening and Protect Valve Life

If your control valve often operates at a small opening, consider the following technical adjustments:

1️⃣ Reduce the Valve Pressure Drop (ΔP)

Lowering the pressure drop across the valve increases the required valve opening to maintain the same flow. This can be done by:

This ensures the valve operates in a healthier range while reducing cavitation risk.

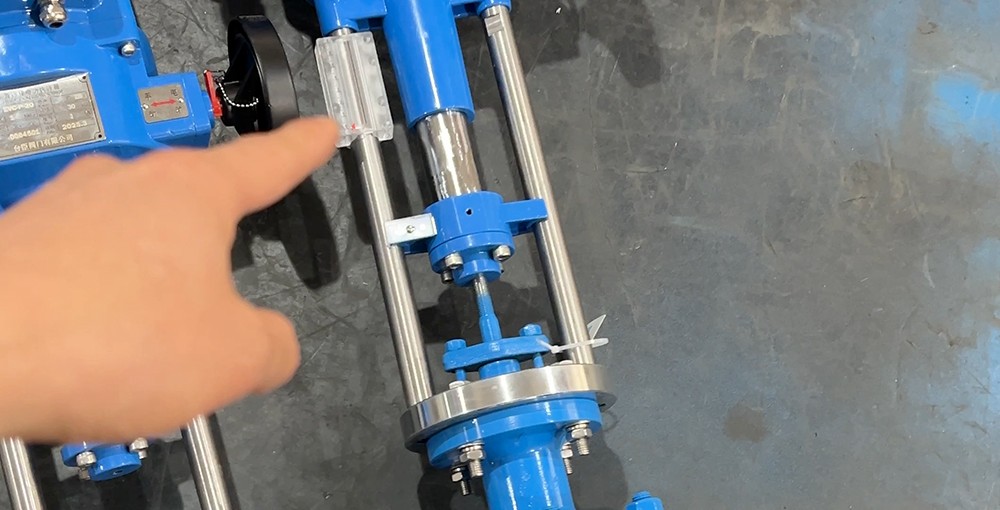

2️⃣ Downsize the Valve

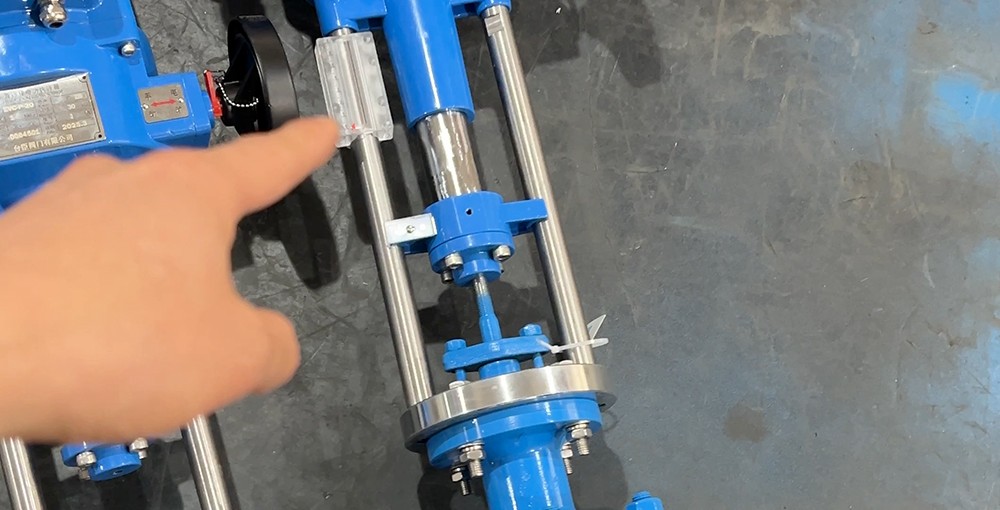

Reducing the valve size increases its working opening for the same flow rate. You can:

Replace with a smaller valve, e.g., swap DN32 with DN25.

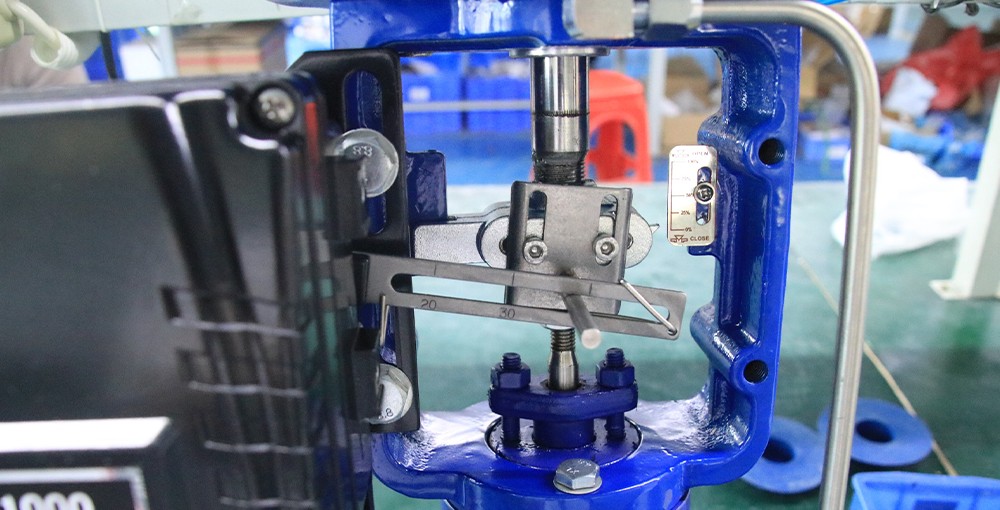

Change only the internal trim (valve seat and plug) to a smaller size without replacing the body — e.g., changing from dg10 to dg8.

Practical Tip:

If your current valve is oversized due to changes in process conditions, downsizing is often the most effective long-term solution.

✅ Final Thoughts — Choosing the Right Valve for Optimal Performance

Ensuring your control valves operate within their ideal opening range is critical for:

Maximizing valve lifespan

Enhancing control precision

Reducing maintenance and downtime

Preventing system instability and leakage

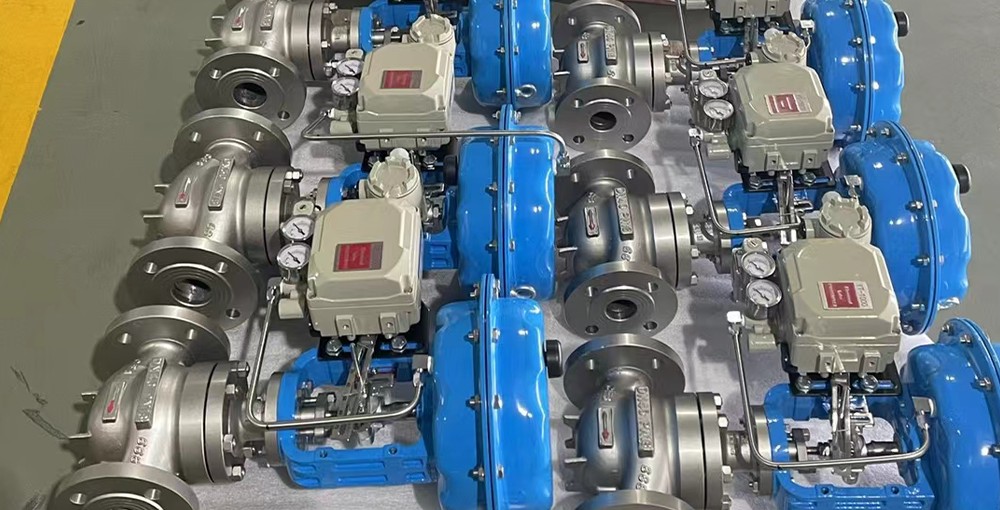

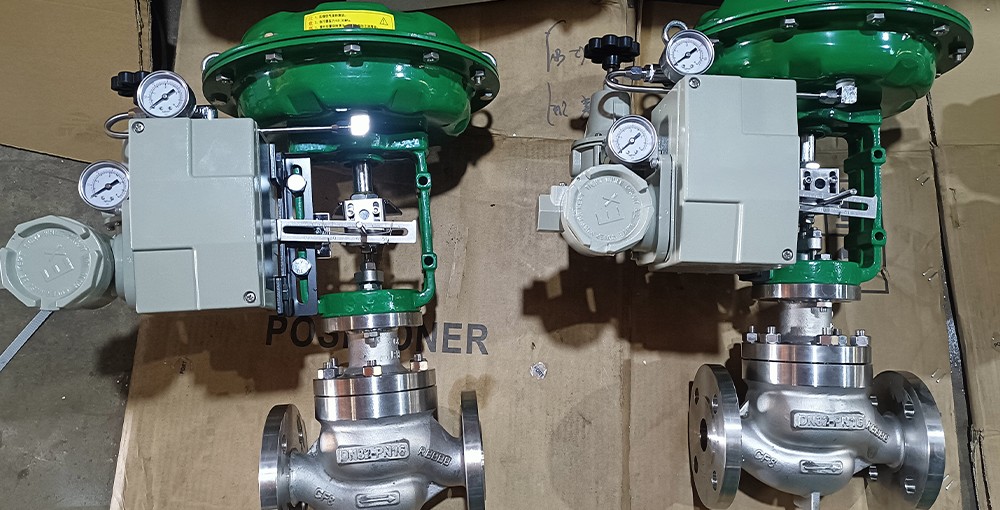

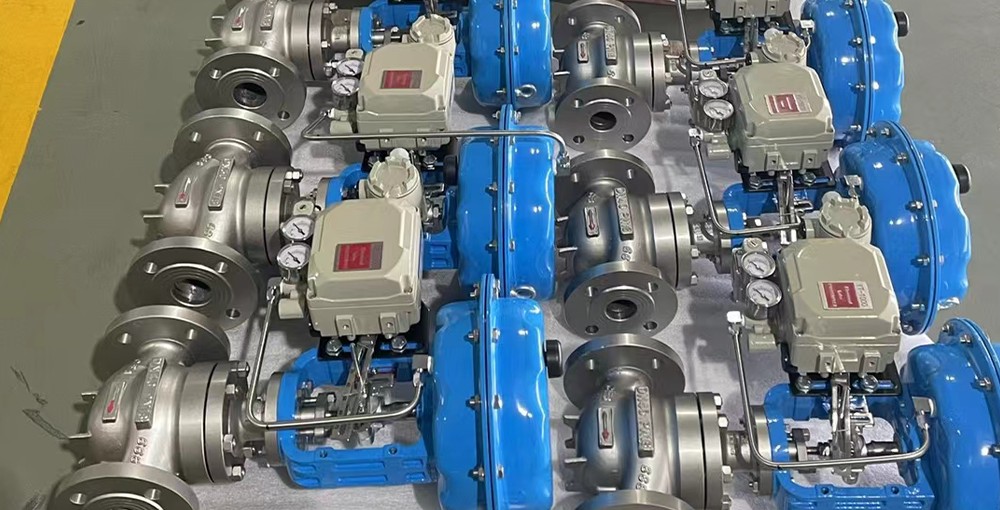

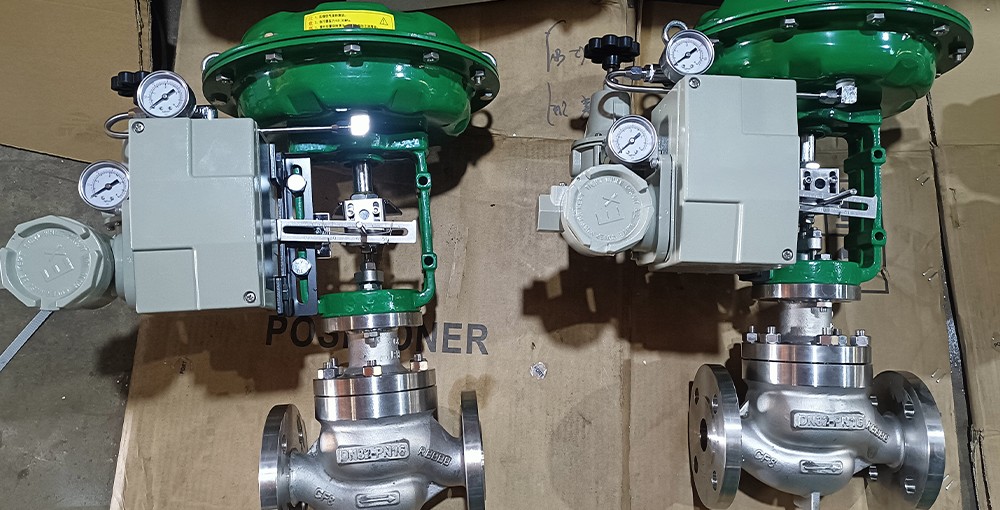

At COVNA, we specialize in designing precision-engineered control valves tailored to your process needs. Whether you're operating in chemical plants, power stations, or water treatment facilities, we offer:

Custom valve sizing

Anti-cavitation and anti-corrosion designs

Smart valve solutions with actuator integration

Fast delivery and technical support

Contact us today to optimize your flow control system and extend your valve life — or request a free consultation for valve selection!