Video

| | |

| Employees explain COVNA pneumatic angle seat valve | Employees explain the difference between electric butterfly valves aand pneumatic butterfly Valves |

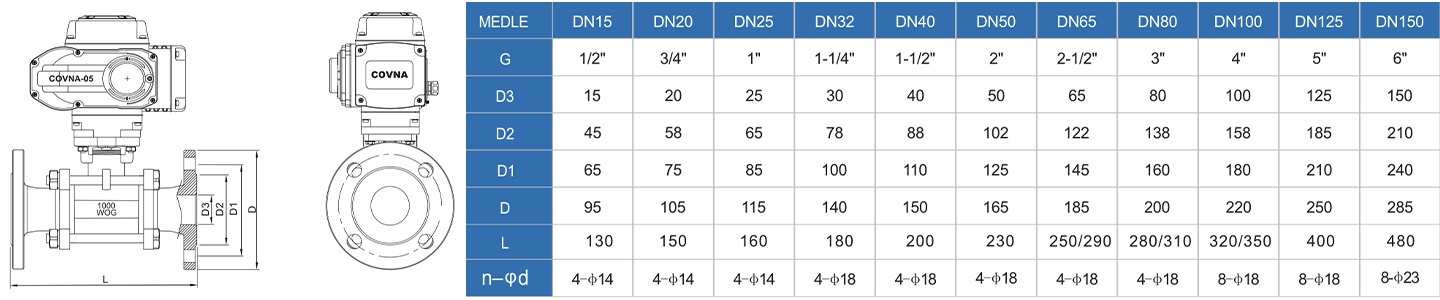

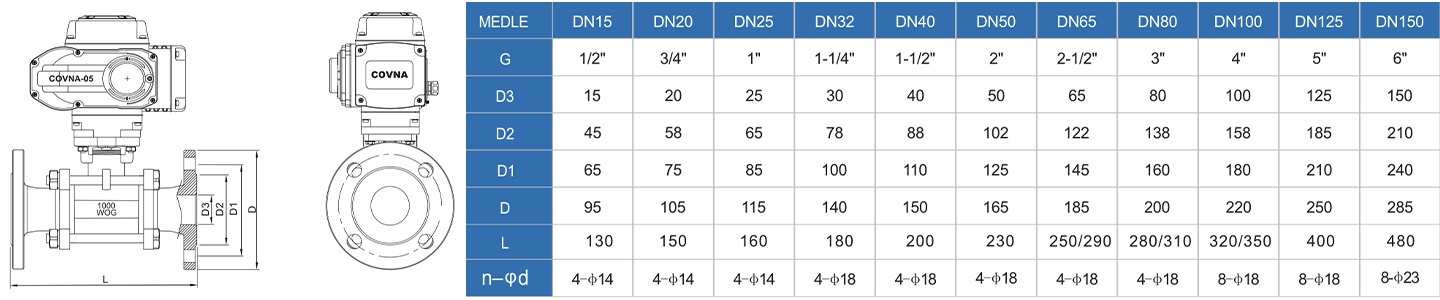

Parameters

Why choose COVNA

1. Rigorous 5-stage pressure and airtightness testing ensures 99.8% qualification rate, backed by a 5-year lifespan guarantee

2. Full EAC certification for all series

3. Comprehensive range: DN15-DN400, materials include cast iron/WCB/stainless steel/plastic, with multi-angle actuators for extreme operating conditions

4. Valves can be manufactured according to your technical drawings with laser-engraved company logos

5. Russian office launched in December 2024