Video

| |

COVNA Product Showroom | Employees explain COVNA pneumatic knife gate valve |

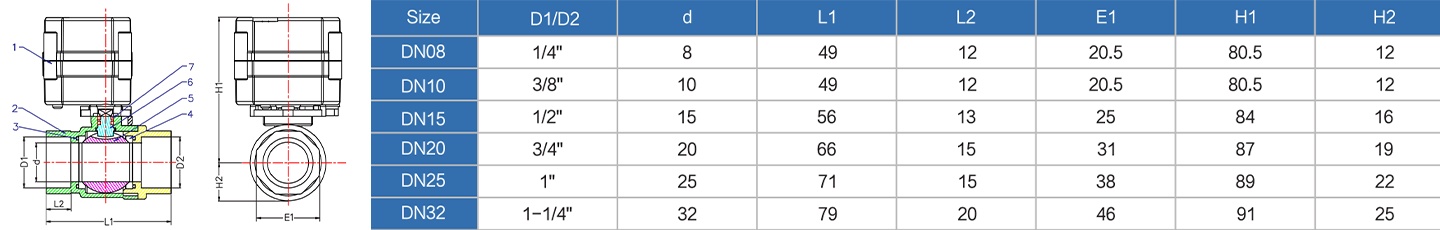

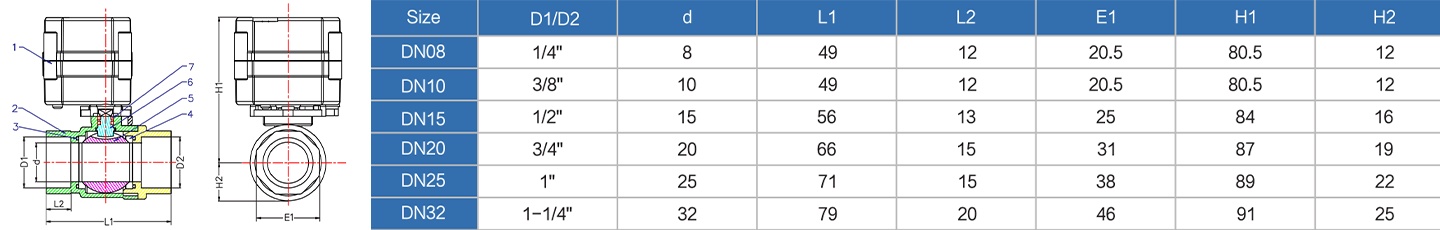

Parameters

Why choose COVNA

1. Contributes to the "Industrial Valve Low-Carbon Standard" and adopts solar-powered facilities, reducing carbon emissions by 27% compared to industry averages.

2. Supplies hydrogen battery valve assemblies to CATL, achieving a pipeline leakage rate reduction to 0.008% for Sinopec, and introduces intelligent wastewater treatment valve systems at the Shanghai Environmental Expo.

3. Holds 18 global certifications such as CE (EU), TÜV (Rheinland), SIL (Functional Safety), and API 6D, meeting stringent standards for nuclear power, chemical, and other high-risk industrial scenarios.

4. Possesses proprietary fluid control valve technologies, including explosion-proof solenoid valves and vacuum equipment-specific valves, with customized hydrogen energy battery valve solutions for the new energy sector.

5. Global R&D network: U.S. office (2021) and Russia office (December 2024), serving 86 countries with valve innovation leadership