What Is a Valve? A Complete Guide

Whenever water or gas flows through pipes, whether at home or in a factory, there’s a small part that helps control it. We call that part a valve. Commonly known as a valve, this device is responsible for regulating, directing, or stopping the movement of fluids.

Knowing how these parts work is helpful. This helps not only engineers and repair workers, but also people who buy machines, design systems, or run factories. In this guide, we explain what they are, what types you can find, where people use them, and how you can choose the right one.

What Exactly Is a Valve?

A valve is a part that controls how water, gas, or thick liquids move by opening or closing pipes.

You can find these parts everywhere—in oil fields, water plants, food factories, and labs. Despite their diverse applications, the core function remains the same: to control flow with precision, safety, and reliability.

" In simple terms, a valve is like a traffic light for fluids—it lets them go, slows them down, or stops them entirely."

A Brief History of Flow Regulation Devices

Flow control dates back thousands of years. Ancient civilizations used basic wooden stoppers or stone plugs in aqueducts to manage irrigation. The Industrial Revolution introduced cast-iron valves that could shut off flow. By the 1900s, well-made brass and steel valves became common.

Today’s devices are highly specialized. Some valves use sensors and electric motors to work automatically when pressure or temperature changes. Some people operate them by hand, but manufacturers make them strong to handle tough conditions.

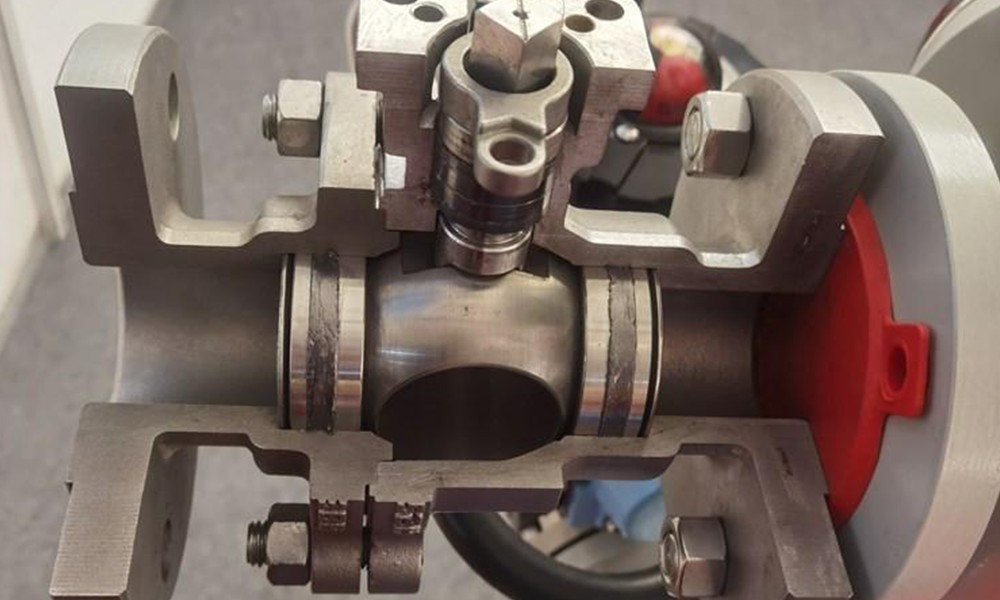

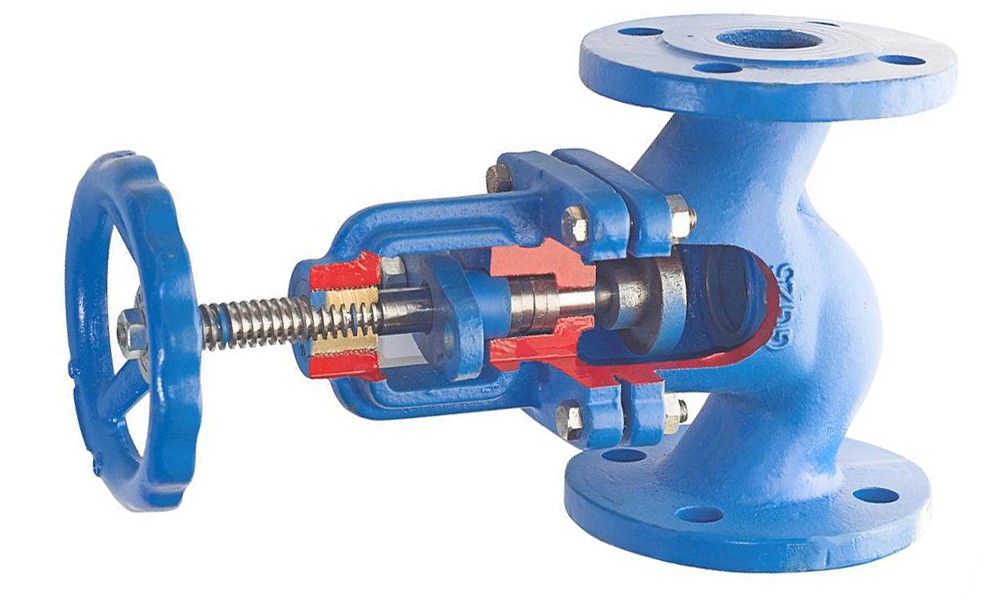

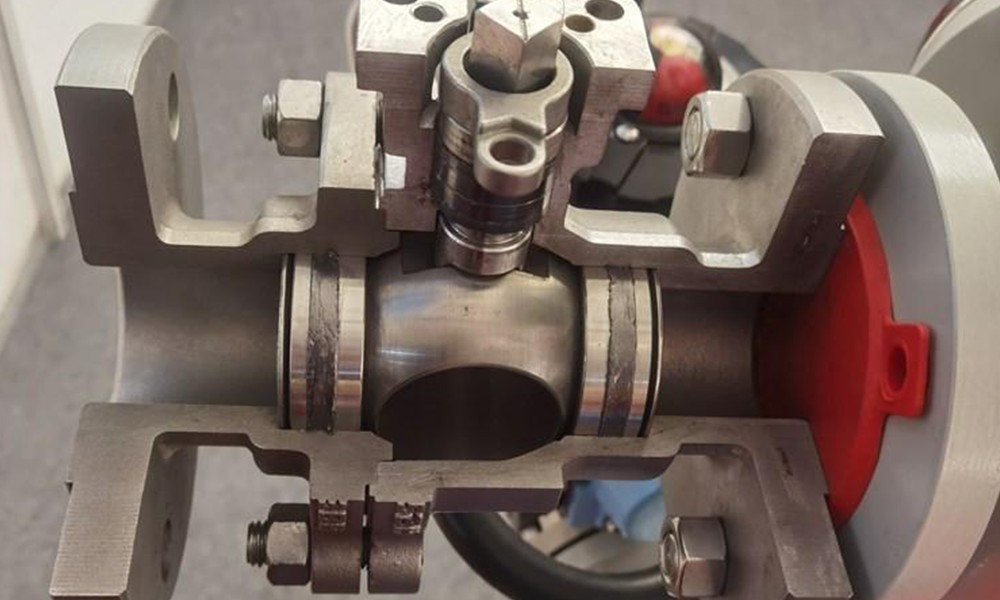

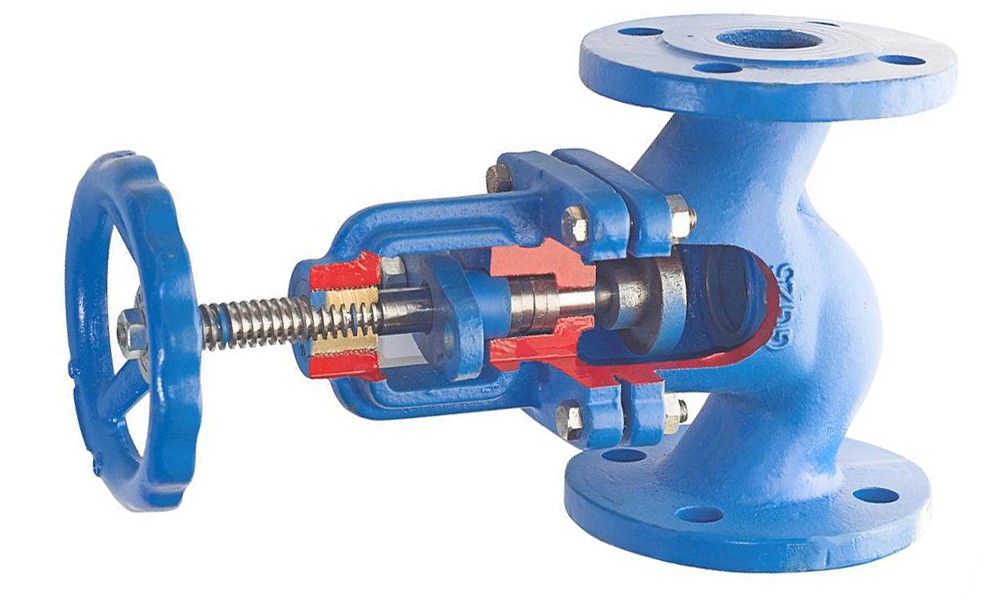

Key Components of a Flow Control Unit

Despite variations in shape and function, most of these devices share several common elements:

• Housing (Body): The outer shell that contains and protects internal mechanisms.

• Obstructor (Disc, Ball, Gate): The moving component that modifies the flow path.

• Connector (Stem): Transmits motion from the handle or actuator to the internal disc.

• Sealing surface (Seat): Ensures leak-tight closure.

• Actuation method: The means of operation—manual (e.g., handwheel), electric, pneumatic, or hydraulic.

Some systems also include feedback loops, position indicators, and diagnostic sensors for remote monitoring and control.

Common Types and Their Functions

Several common designs exist, each made for specific operating conditions:

Ball-Type Control

• Utilizes a spherical element with a hole.

• Offers rapid shut-off and minimal leakage.

• Ideal for pipelines transporting gas, water, or corrosive fluids.

Gate Mechanism

Globe Design

Disc (Butterfly) Model

• Employs a rotating disc inside the pipeline.

• Lightweight and cost-effective, especially in large-diameter systems.

↩️ One-Way Check Style

Pressure Relief Device

Materials and Manufacturing Options

The choice of materials used depends on the working environment:

• Stainless steel: Offers excellent corrosion resistance.

• Brass and bronze: components are typical choices for plumbing systems and other environments with low pressure.

• PVC/PP: Lightweight and chemical resistant, ideal for water or mild chemicals.

• Duplex/super duplex alloys: Used in offshore and subsea systems.

We make custom fluid control parts that fit your needs. You can choose the material, size, and how they work to match your system.

Where Are Flow Control Devices Used?

Here are a few examples of major applications:

Industry — What They Do

• Water treatment: Stop or control flow, adjust pressure, and manage filters

• Oil & Gas: Shut off flow for safety, control wellheads, and manage pipelines

• Food & Beverage: Keep fluids clean and sanitary

• Pharmaceuticals: Control sterile flow for pure production

• HVAC systems: Control temperature and pressure

• Marine and shipbuilding: Manage fuel, ballast, and cooling on ships

The choice of flow regulation equipment can significantly affect system safety, energy efficiency, and compliance with industry regulations.

Installation, Operation, and Maintenance Tips

Proper installation and maintenance are crucial:

• Always ensure compatibility between the control unit and the piping system.

• Avoid overtightening; it may damage seals or threads.

• Use appropriate torque settings for actuators.

• Schedule periodic inspections to check for wear or corrosion.

• Replace seals and gaskets as part of routine maintenance.

Smart devices may include built-in diagnostics or sensors that notify operators when performance degrades or a component needs replacement.

Innovations in Flow Control Technology

The world of flow regulation is evolving fast. Today’s advanced systems include smart valves that connect to control networks and can be monitored remotely. These devices can adjust flow based on real-time data, improving efficiency and safety.

For instance, in oil and gas pipelines, sensors detect pressure changes and automatically adjust flow to prevent accidents. In water treatment plants, valves work with computer systems to balance flow rates and maintain water quality.

Additionally, environmentally friendly materials and designs are becoming more popular, helping reduce waste and energy use. Manufacturers continually develop new sealing materials and coatings to handle more aggressive fluids and higher temperatures, extending the valve’s lifespan and performance.

Custom Solutions for Unique Challenges

Every industry and application can present unique challenges. Some fluids may be highly corrosive, others may require extremely precise flow control, and some systems operate under extreme temperatures or pressures. Off-the-shelf products may not always fit these special needs.

As a professional manufacturer, we work closely with customers to design and produce custom solutions. Whether you need a valve that can handle abrasive chemicals, or one that fits a space with unusual size restrictions, we can tailor the design to meet your exact requirements. This level of customization helps improve safety, reduce costs, and increase productivity.

How to Choose the Right Flow Regulator

Here are the core selection criteria:

• Medium characteristics: Is the fluid clean, dirty, corrosive, or pressurized?

• Operating conditions: Pressure range, temperature, flow rate.

• Control method: Manual, electric, pneumatic, or automatic.

• System design: Pipe size, layout, flow direction, and space constraints.

• Certifications: Compliance with standards like API, ASME, ISO, CE, or FDA (for food-grade uses).

Still unsure? Our engineering team can assist with sizing, material selection, and automation options.

Why Partner With a Trusted Manufacturer?

A substandard component can cause:

• Leaks and pressure drops

• Environmental hazards

• Downtime or process failure

• Higher maintenance costs

Our factory is equipped with CNC machining, advanced testing labs, and a full quality control system to ensure every product delivers long-term performance. We offer:

• Over 100 models including rotary and linear types

• CE, ISO, and industry-specific certifications

• OEM and ODM services for global clients

• Responsive after-sales support

Final Thoughts

Understanding how flow control devices operate—and choosing the right one—is essential for building reliable, efficient, and safe systems. Whether you're designing a new plant or upgrading existing pipelines, the right equipment ensures smooth operations and long service life.

✅ Looking for reliable, precision-engineered fluid control products?

We specialize in manufacturing high-performance components for industrial flow control.

Contact us today for a custom quote or free consultation