Video

| |

| Employees explain COVNA multi-turn electric flange ball valve | Employees explain COVNA explosion-proof electric valve |

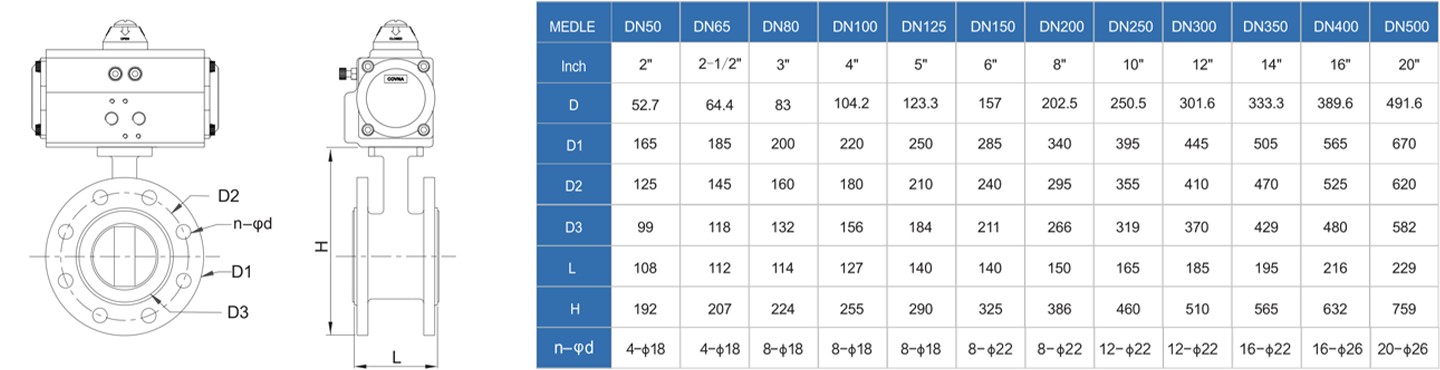

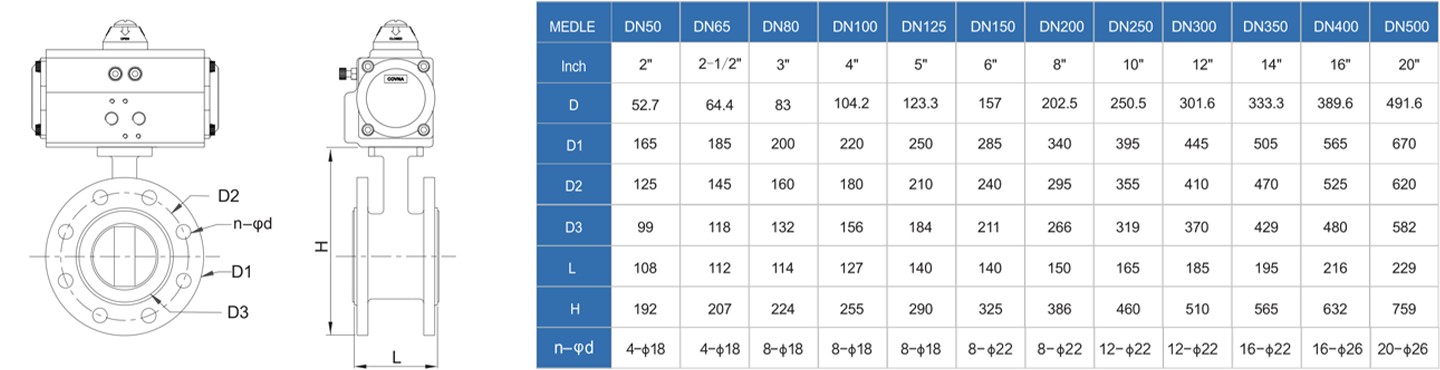

Parameters

Why choose COVNA

1. At the same time, it has a complete control valve and ball valve assembly workshop, covering an area of 6,800 square meters, with a daily output of 5,000 control valves and ball valves

2. Optional anti-corrosion coating, suitable for corrosive environments such as chemical and marine

3. The US COVNA Division was established in March 2021 to provide fast and convenient services to North American customers

4. COVNA brand has been established in 33 countries and regions and has registered trademarks

5. At the same time, it has a complete control valve and ball valve assembly workshop, covering an area of 6,800 square meters, with a daily output of 5,000 control valves and ball valves